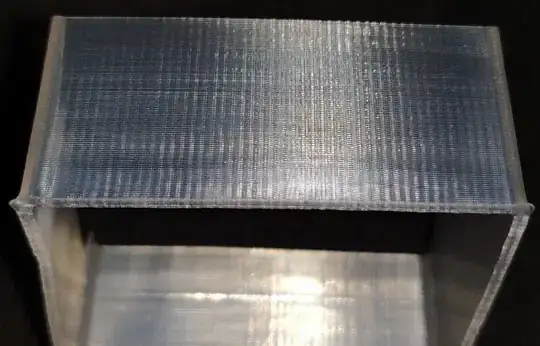

The fact that these are all perfectly spaced, and don't mirror the edges of irregular prints, makes me think it's definitely not ghosting. That said, I can't see the Y direction on either print, just the X direction, so this all assumes it's only happening in one direction.

One thing to think about: Your motors have typically 2 opposing coils, and they get activated by taking 4 steps: (North, off, South):

N/o

o/N

S/o

o/S

If these are spaced out exactly 4 steps apart, that would imply that one of your coils is either underpowered or overpowered on the motor controlling that direction's movement. That would lead to your motor torque dipping and increasing, leading to slightly uneven print speed. This is 100% speculative and might be a goose chase since you've got 4 X/Y motors and it seems to happen in both the X and Y axis. The chances of having that many motors exhibit the same deficiency is astronomical.

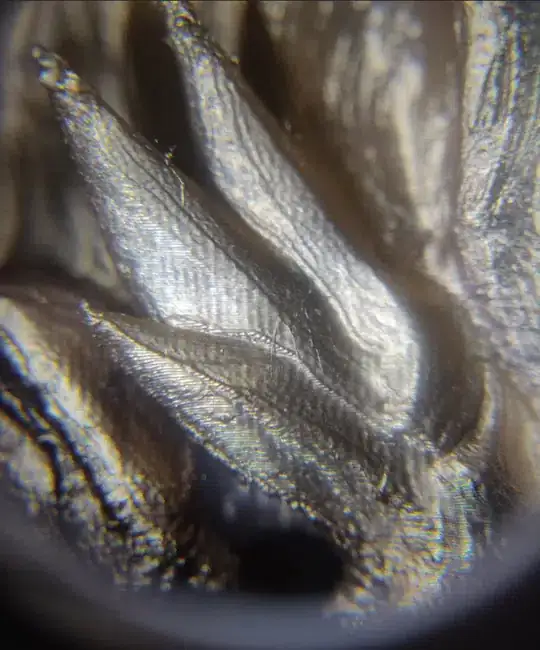

That said, I've got little experience with multiple motors per axis. Another thing you might look into is whether the motors are fighting each other at all. If, for example, the motor-side pulley isn't aligned exactly the same way on both X motors, or the motors get out of sync with each other, because of the way the motor's holding torque falls as you get away from a full step position, you might find that one motor is holding the other back slightly, or pulling it forward towards the nearest full step. Again, this is all speculative, but it might be worth looking into. You can typically figure out the full step location by killing power to the machine and letting the motors settle into a full step on their own without the belts or other drive mechanisms attached. I'd unhook the belts, kill the power, get the motors settled (with a bit of a nudge if necessary), and then see if your belt perfectly settles into both pulleys in that location. You might find that the belt teeth don't quite line up on both pulleys, and the only way I can think of that would fix that specific problem is spinning the motor until it matches, or even physically relocating the motor closer or farther relative to the other on the same axis.

YMMV, best of luck.