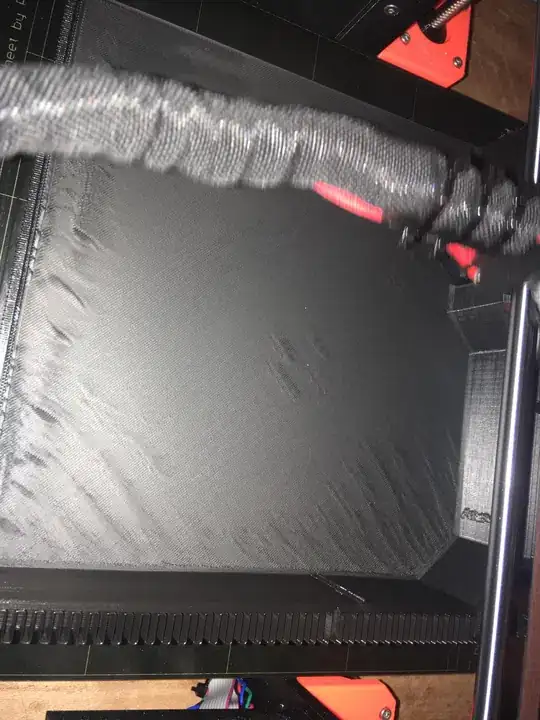

Recently started using my kit Prusa I3 Mk3 and noticed that with large horizontal surfaces a wrinkling pattern is emerging.

As you can see in the image the wrinkles seem to run parallel, the surface is 10 mm above the build plate with all bridges fully supported.

Has anyone seen this before? All other areas seem to be doing well.

This print uses PLA filament @ 235 °C hotend temperature and clearly shows a wrinkled pattern on the top layer

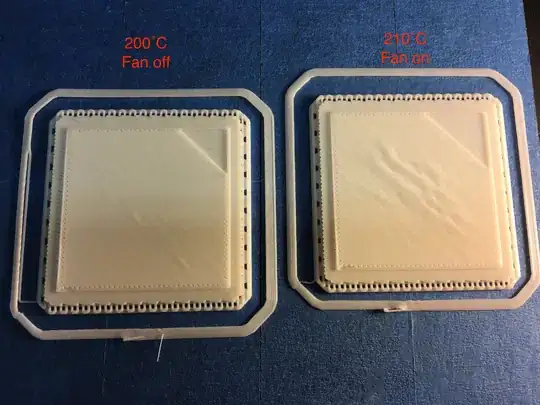

If it helps, I haven't changed the settings from the normal Prusa Slic3r 0.15 profile.

The problem reduced to an acceptable level by reducing the temperature to 205 °C but keeping the fan speed 100 %, I am printing PLA. I might reduce the fan speed if I feel troubled by the result.