Around about 2 weeks ago I upgraded my Ender 3 Pro with a micro Swiss direct drive and all metal hotend. I had some tuning with the PID and e-steps to do, but once that was done, it's been mostly good. However over the past week I've been having problems where my prints appear to have waves in them and after I've levelled the bed and the print gets about ~5 layers in it sounds like the nozzle is grinding against the print and I drop the bed down which I've noticed is something I keep having to listen for and intermittently drop the bed down mid-print.

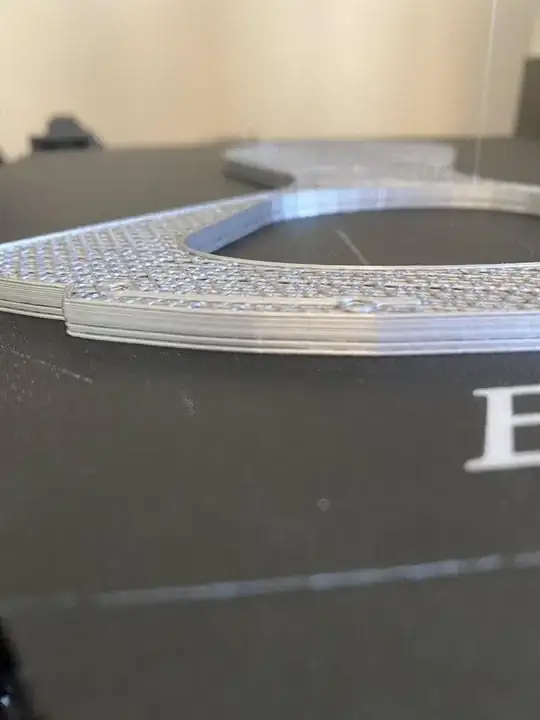

I thought maybe my bed level was a little high so I went through the bed levelling with my DTI and ran chep's bed level print and watched the print and the filament was being laid down perfectly, adhesion was good and not flat. However I've been trying to print a kitchen roll holder and this is the state of the first few layers:

The layering below is where I've had to manually drop the bed mid print. I was wondering if there's a problem with my Z axis but when I manually move up and down it's fine and I even did a similar check where I measure 100 mm from the top of the bearing and set it move 100 mm on the controller and it was spot on.

My print settings/configuration as follows:

- Ender 3 Pro with magnetic build plate and Micro Swiss direct drive

- Bed temp: 60 °C

- Hotend temp: 210 °C

- Slicer: Cura 4.7.1 ( recently upgraded from 4.5.1 - wondering if that's the problem? )

- Filament type: PLA

- No cooling fan

I'm honestly, very stuck at the moment at what to do for the best! I have a BLTouch to install but I don't want to install it until I understand what the cause/fix for this issue is. I prefer to know pre-upgrade everything's fine so if there are issues from upgrades I can rollback to a working configuration. Any help / advise on diagnosing this issue would be appreciated! If there's any info I've missed, happy to update with it. I have only had my printer for about 6 months so still a bit of newbie.

I'm currently running a series of tests to check the temperature combinations and to see what gives me the best results. I'm starting at 210 °C and running through all bed temps 40-70 °C to check for waves with 0.5 mm height square, then running the best results through a height test with the XYZcube to see if the height issue goes away. Does anyone know if there's a way for me to batch these tests using Cura post processing similar to a temperature tower? I want to change the bed temperature per model.