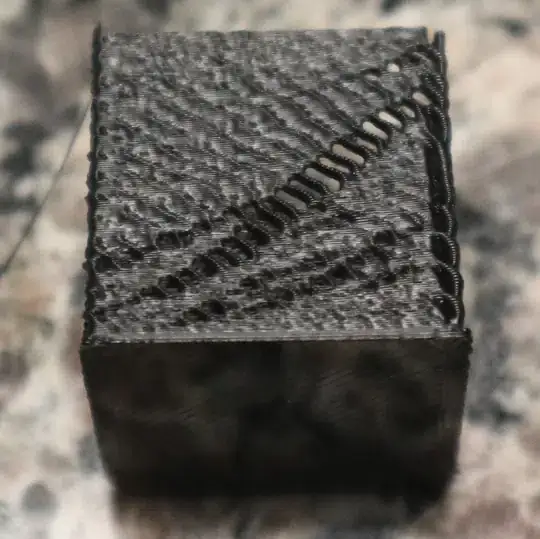

Issue: My Ender 3 is creating distorted prints with layer separation and deformations.

Can anyone point me in the right direction?

Setup:

- Ender 3

- TH3D EZABL Auto Bed Leveling

- 1.75 mm ABS filament (245 °C)

- Heated Bed (100 °C)

- Sliced in Ultimaker Cura (with 1.75 mm filament diameter and 0.2 mm layer height)

What I have tried:

- Tightening Z axis screw

- Tightening Y axis belt

- Tightening X axis belt

- Switching to a different spool of ABS

- Printing a temperature tower (same problem across different temperatures)

- Turning off the auto bed leveling.

Update:

- I've measured the temperature of the hot end, it is reading around 205°C +- 20°C

- As per suggestion from the TH3D support team, I tuned the PID of my hot end. Unfortunately the results did not turn out much better (1,2) and the support technician is suggesting(a long with many people from the comments) that I should try to replace the thermistor. As per suggestion from @Trish, I measured the impedence of the thermistor and it does seem to be somewhat off from stock (118kΩ vs 100kΩ). Will update again once the replacement arrives.

- As requested, here are some more photos front, back, left side, right side. The cube isn't hollowed out just to save material while I calibrate the dimensions.

- I printed the same cube out, rotated 90 degrees. I got similar results though: front, back, left side, right side.

- Swapping the nozzle out solved the issue! Thanks for the help everyone!