Your video shows that your bed seems warped somewhat.

Ammount of error

As I assume you did level the bed with a sheet of paper to be 0.1 mm thick, we can estimate the change of thickness. The thickest point seems to be 0.2 mm, the thinnest 0.05. that's in average an error of 0.075 mm for the first layer. If you can live with that, no need to touch it.

Fixing the issue

Basically, if the error is too large for your liking, you need to fix it. To fix it, there are pretty much 2 ways. Remember that the Ender-3 uses 24V when ordering parts!

Fix the part or install a replacement part

If you feel like you need to get it even flatter, you'll need to try to flatten the bed mechanically or replace it. You'll need to be comfortable to remove the BuildTak-clone surface, then remove the leveling screws, open the electronics enclosure, remove some hot glue, unhook the bed.

Then you will need to flatten the bed in some way (grinding the upper side perfectly flat or bending it, replacing it for an entirely flat one).

Then reinstall it, going through the uninstallation backward, and add a new build surface on it.

Switch to alternate leveling method: Mesh Bed Leveling

If you consider yourself to be able to do some intermediate to advanced modification of your printer, you can change the hotend carriage to one that allows mounting a distance sensor and changing the firmware to mesh-bed-leveling.

You'll need to get an induction or capacity sensor (common operation ranges for those are 6-36V, so perfectly fine with 24V) and some way to couple that to the board, most likely an optocoupler. Print a new mounting for sensor and fans.

To install you open the electronics compartment, hook up your chosen 24V-5V coupler as extra to the Z-switch, hook the power supply of the sensor up and run it up to the printhead. Replace the mounting for the hotend cooling fan and part cooling fan and change your firmware. Calibrate the height of the sensor to trigger correctly.

I did flash a bootloader via the ISP on my ender-3 since then, so I can just flash the new firmware via a direct connection.

Last words

In either way, after fixing, you should run a PID-tune on the machine.

Thermal Runaway might or might not be active, depending on your firmware iteration, so you should update it anyway, which might make Mesh Bed Leveling the slightly easier way to go.

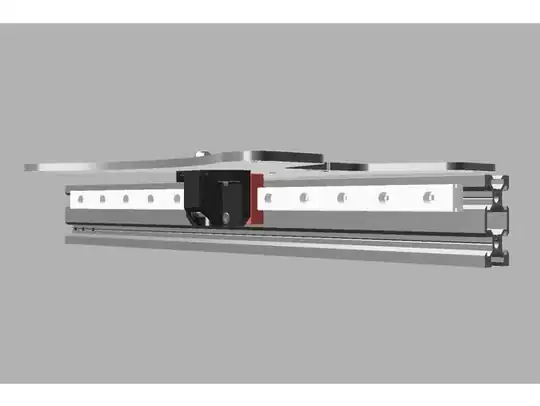

This has nothing to do with the bed carriage wheels, as the bed hangs onto the carriage only via the screws in the corners.