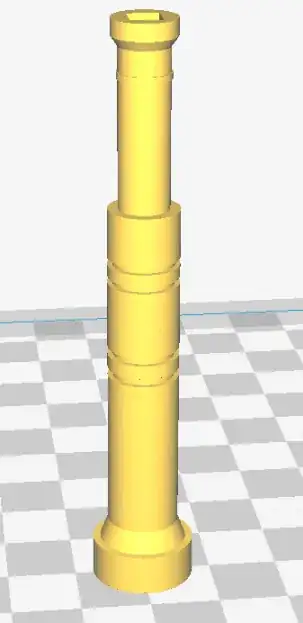

The answer by fred_dot_u is fine for small prints with relative low cost or batch producing, where a single part is needed several times. But if you print something big or unique it's not cost effective. Slowing down the complete print is also not very time efficient.

In Cura there an option called Mininum layer time, which addresses this problem:

Cooling -> Minimum Layer Time / Minimum Speed

This means that it will only slow down when the print distance for a particular layer is short. Giving the material some extra time to harden. Other layers will be printed at normal speed. Increased print time will be limited this way.

For your situation I would advise you to increase the part cooling, if possible, in conjunction with configuring the Minimum Layer Time option mentioned above.