I'm new to 3d printing, so I might be missing something obvious. If so, please let me know.

I printed my model successfully yesterday, but today I'm trying to print the same model and the first layer refuses to adhere, which means at best several layers after that are messed up if it manages to recover, but usually it just means I have to cancel and start again.

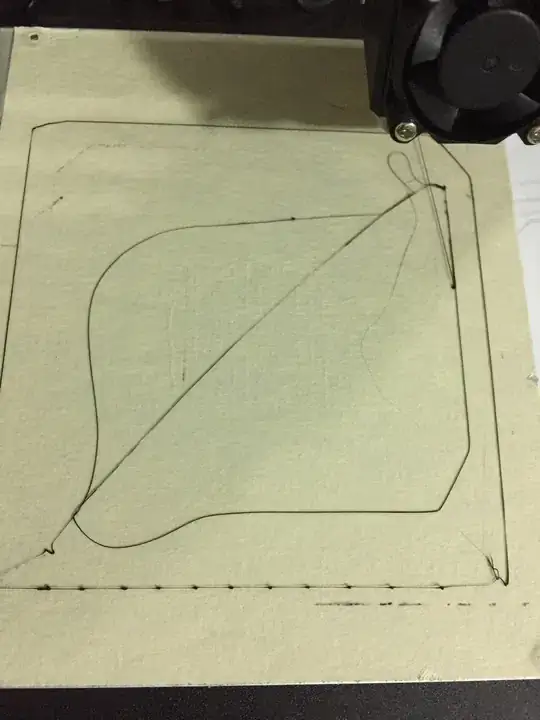

It will print one horizontal line (across the x axis), then when it tries to vertical line (across the y axis) the horizontal line doesn't adhere and gets dragged along with the print head and everything is screwed up.

I've tried leveling the bed over and over again. (I use a sheet of paper and try to slip it between the bed and printhead. I adjust the bed so that I feel a bit of resistance as I push and pull the paper under the printhead.)

I've tried increasing the preheat on the printhead and on the bed. I'm using black PLA 1.75mm that says it has a print temp of 205-225. I've tried printing at 205, 210, 215, 220, and 225. I've tried a bed temp of 50, 55, 60, 65, and 70.

I've tried setting the print speed multiplier to 0.5 to give it time to adhere, but no changes.

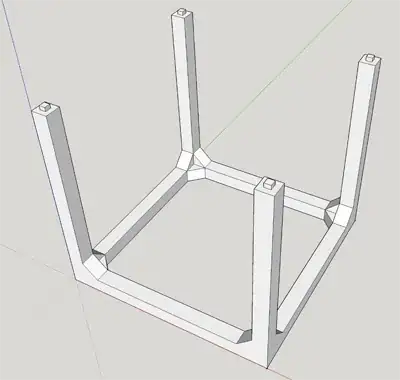

I'm trying to print something a wireframe cube that is at the extent of my printable size, so I don't know of a way to use a raft or a brim to help adhesion.

This is what my model looks like:

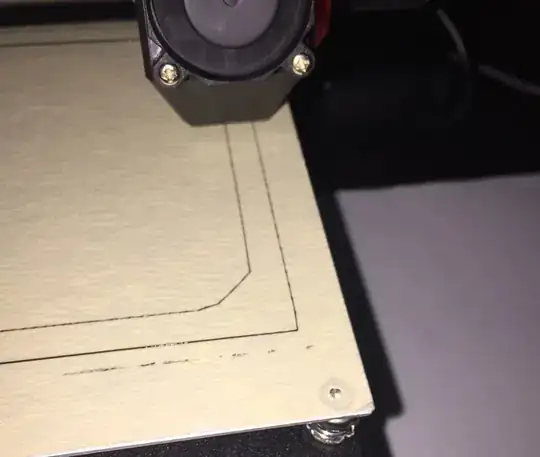

When I printed a good one yesterday, here is what the first two lines looked like:

When I print today, even after multiple attempts to level the bed, this is what the first layer tends to look like:

I'm using a Monoprice 15365. I created my model in SketchUp, then exported as STL, which I imported into Cura 2.3.1. Then I used Cura to export a gcode file to an SD card. I put the SD card into my 3d printer and printed from there.

Any advice is welcome. I don't know if the problems I'm having are because the bed is too low or too high or too hot or too cold or if the printhead is too hot or too cold... nothing I've tried seems to change the results.