I've actually solved this, but I think its still a useful question which I don't think is easy to answer with existing questions.

As soon as I'd built my ANET-A8 (Prusa i3 DIY kit), I found I was having problems with the extruder crashing into the bed. Although I thought I'd adjusted the bed leveling OK, the calibration seemed to keep getting messed up.

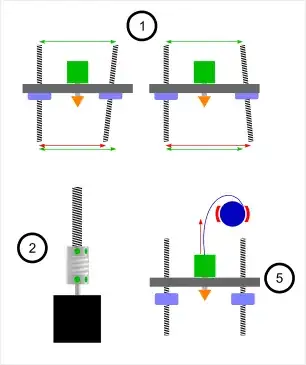

I tracked this down to two factors. First, I was winding the extruder head up some distance before loading the filament and starting a print. Second, at roughly half-way up the axis, the right-hand thread seemed to be getting stuck (more often when moving up than down).

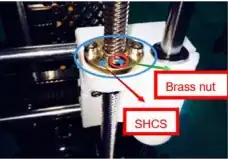

What wasn't clear (and not mentioned in the building instructions) was what might cause this problem.