I'm trying to design a camera handle, which will be around 8" long and will have a brass camera thread insert in the end, where the camera will be mounted. (That way, I don't have to screw the camera thread into plastic which will wear out faster.)

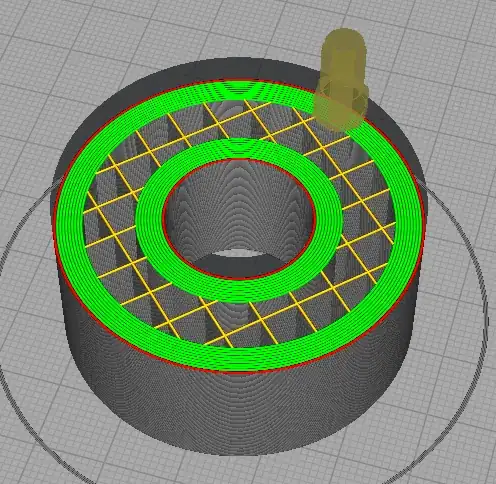

If I print the handle normally, the end of the handle won't be solid so I can't solidly put that brass fitting in. If I set the fill in Cura to 100%, the print will take a very long time and will be unnecessarily solid. I only need a centimeter or two at the end to be solid.

Is there a way to get one particular wall in Cura to be very thick (1-2cm) without affecting the other walls? Is there some other way to get a solid chunk in the end of the part?