I'm using Ultimaker Cura and a Dremel 3D45S with an eSun Nylon filament. As starting point I'm using the default settings of the printer, 260 °C for the hotend and 80 °C for the bed.

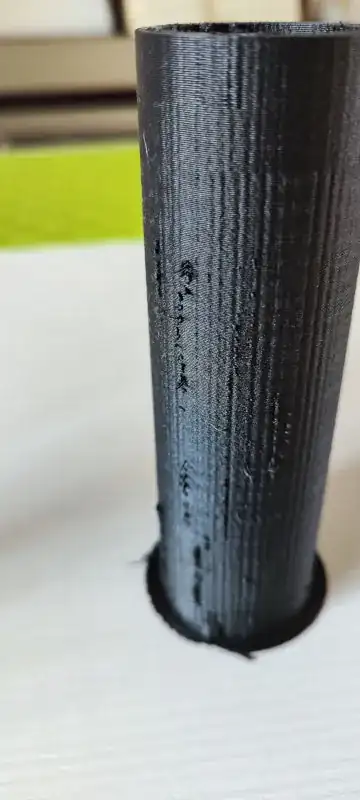

These are the results:

In addition to the poor print quality, the resulting dimensions are wrong. For example, the cylinder is supposed to have a wall thickness of 5 mm, with an inner diameter of 35 mm and the outer diameter of 45 mm. With ABS they are quite good (just a 0.2 mm difference). With nylon they are off by 1 mm! The wall has a thickness of 6 mm.

For both materials the flow is set to 100 %

Any ideas on what I should change to improve the printing?

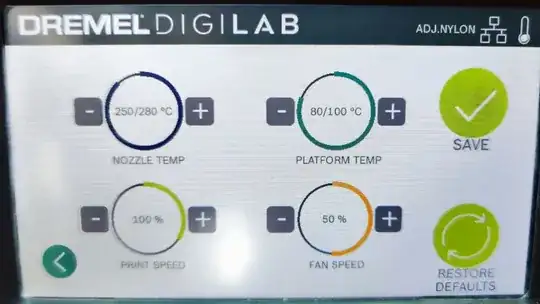

Here my current settings for Nylon: