I'm trying to line up the physical print bed of my printer (Printrbot Simple Metal) to the virtual print area of the slicer (Cura). So far, they've never been properly aligned. It was never that big a problem because, worst case scenario, my print would simply not be dead-center on the bed. But I've decided to try and fix it.

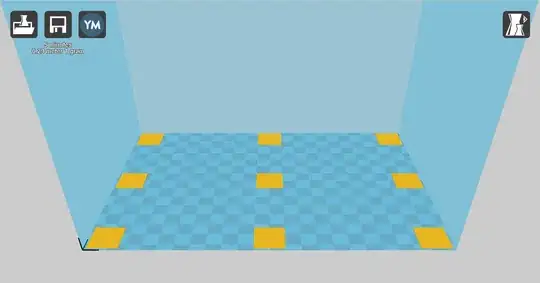

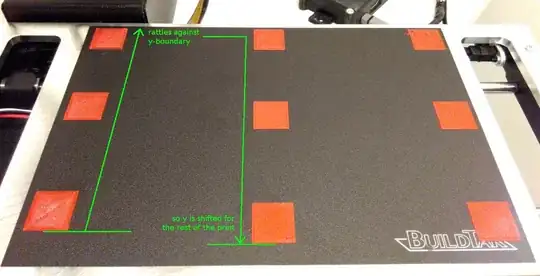

Here are pictures of a test model in Cura, and the resulting physical print:

What's the proper way to align the two? It seems I just got lucky with the x-axis here (though note that the BuildTak surface is a bit off center). But obviously the y-axis needs fixing. The print needs to start a little lower, because print-head couldn't reach the highest point, and the y-axis motor slipped to compensate.

Ideally, the fixed parameters of the print bed size and offset would be set by the Marlin firmware (EEPROM?). But I also need to be able to do a little offset tweaking on the software side for when I need to replace the BuildTak mat.

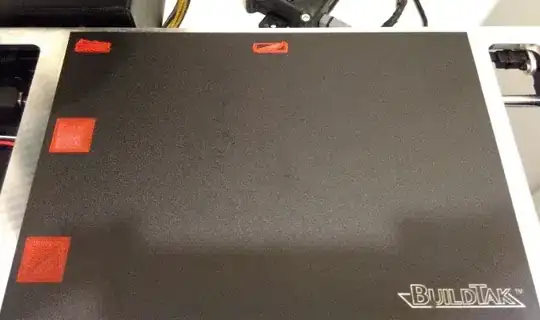

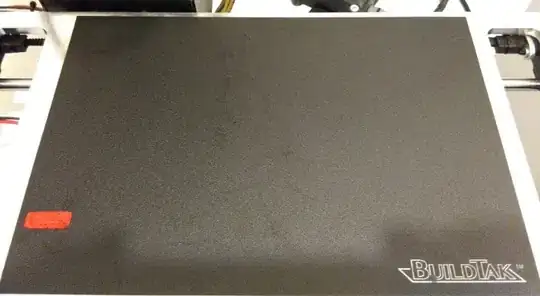

Edit: I tried M206 (home offset) commands, but the result is definitely not what we want. I cancelled these early.

The upper print has M206 Y-15, the lower print has M206 Y15. What seems to happen is that the coordinate system is not physically shifted. Instead, the area is 'cropped'. All filament that should go outside the boundaries is actually extruded 'on the edge', resulting in an ugly blob.