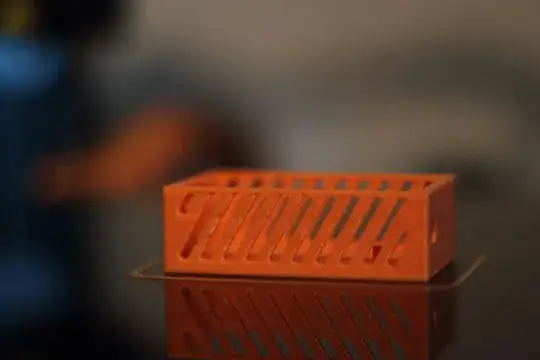

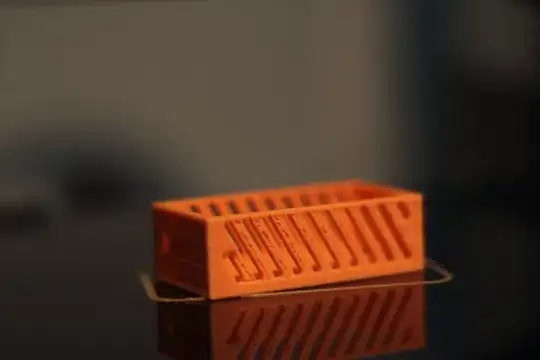

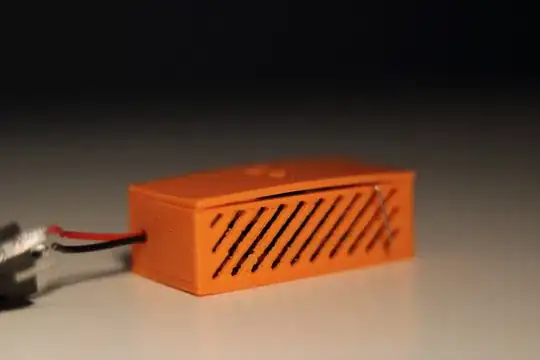

Does anybody have an idea what causes the strange outer wall skin texture? I don't know why this happens; the inner wall looks fine, but the outer wall looks distorted.

Also it's strange that the distortion only happens on the left side for about 2 cm on all prints.

Disabling retraction had no effect. Reducing the printing speed neither improved it.

Edit: I'm printing at 0.16mm layer height with 98% initial flow rate and 94%. No support.

Standard PLA with the standard nozzle at 190°C. I am using Cura for slicing if it matters.

Printing speed is at 40mm/s for the outer wall and 80mm/s for the inner one. I already tried to decrease the outer wall speed to 20mm/s without any luck. Except for one other print, I never had an issue with those settings.

I just finished a print with 100% flow rate to exclude its the flow rate.

With 100% only the front improved at all.