Nomenclature help

- A Layer is everything that is printed between the print head moving upwards.

Layer height is how tall each line is. It is in Quality.

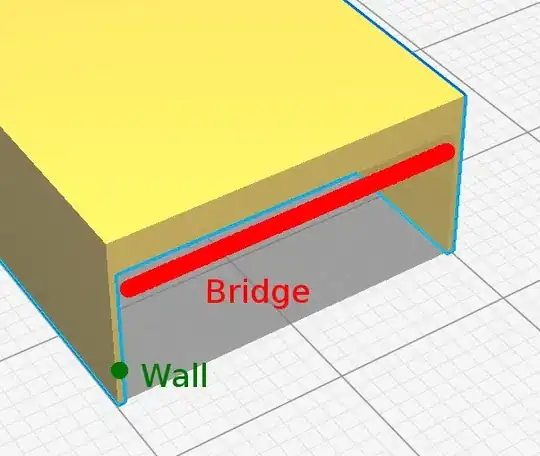

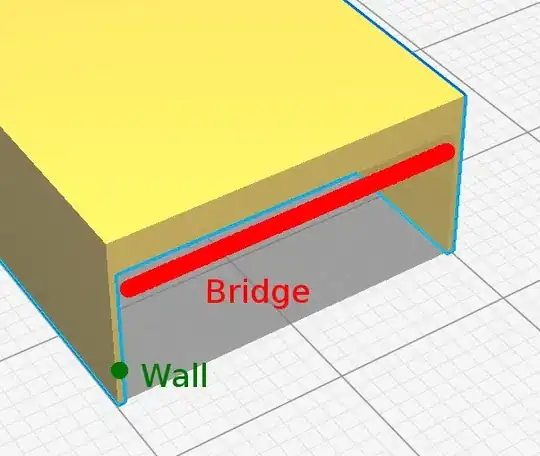

- A Wall is made up from lines put down next to each other.

line width is how thick a 1-perimeter-strong wall is in the XY-plane. It should never be smaller than the Nozzle Diameter. It is in Quality.

- Nozzle Diameter is what is the physical diameter of your nozzle. It is located in the printer configuration.

- A Bridge is printing horizontal layers that connect to walls at the sides but otherwise not connected to the printbed or print.

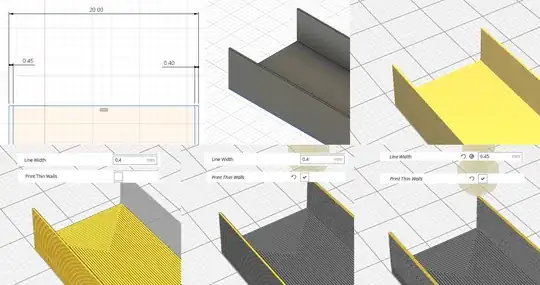

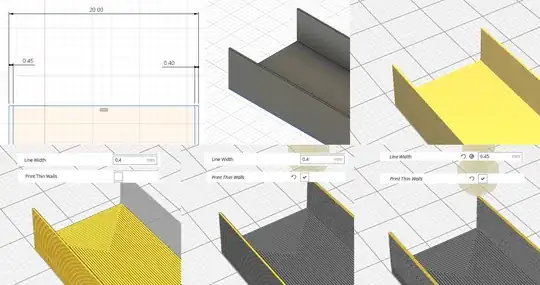

Ultimaker Cura does ignore too thin walls

Your walls are 0.28 mm thick and your nozzle is most likely 0.4 mm thick. That can't be printed at all, in fact, you are way too thin to be printed: a printer should never print any object that is thinner than its nozzle as that is a perfect way to generate clogs.

Atop that, slicers ignore also what is thinner or exactly as thin as the line width. If the line width is 0.4 mm, and the wall is 0.4 mm, it gets ignored. If the wall is 0.45 mm, it is not. This can be remedied by setting the option print thin walls, but you still need to have one line nozzle-diameter as minimum line width - actually it is common to go about 10% larger for better extrusion.

Solution

Strengthen the walls to one line width (usually 0.4 mm) in your CAD-design and activate print thin walls under Shell.