Recently, at work we bought a Guider II printer from FlashForge. When we try to print models using a high resolution or models with a too high printing time, the feeder gets clogged. And the feeder is too hot. We have concluded that the feeder is getting clogged because the high temperature softens the PLA.

We check the feeder fan and is working fine. How can I avoid the jamming? Pausing the 3D printer and wait a few minutes is not working for us. I don't know if it is a common problem for this 3D printer model.

Edit:

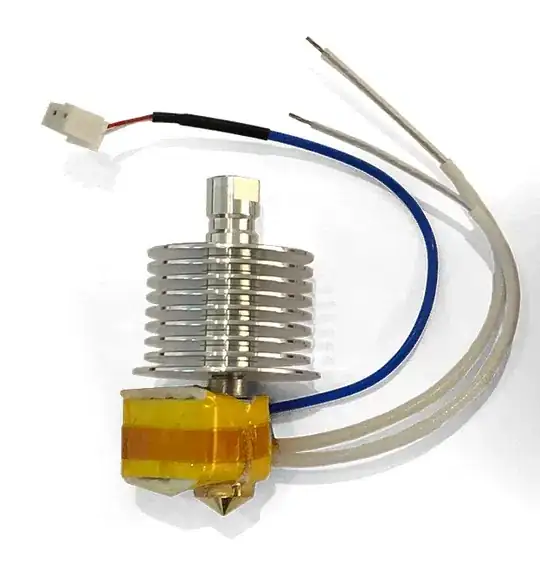

The hotend is an all metal hot end. I can't find more information about the hot end.

In the manual of the guider II flashforge recommend a temperature of 210°C for the head and 30°C for the bed. I have tried different temperatures. The most common temperature I've used is 190°C for the head and 55°C for the bed (I obtain the best results with this temperature).