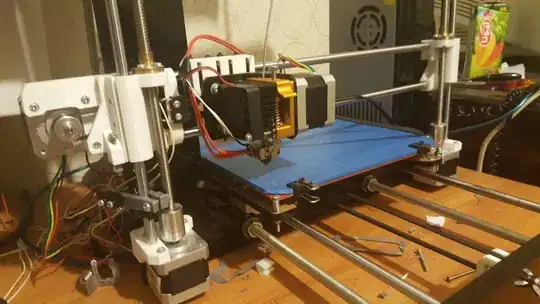

This picture pretty much shows the problem:

I print on a CR-10 and this thing is pretty much just a problem factory. Anyways, the latest problem that was never there before is that for some reason the first 2-4mm of the print are totally messed up like in the picture. That isnt that much of a problem for bigger parts (as in the right one) but smaller things such as the pi-coin (left) are absolutely useless now.

Things ive already checked that haven't fixed the problem:

- Different PLA filament types (geetech, Janbex)

- Different nozzles (0.3mm, 0.4mm)

- Variations of smaller line withs (up to .05mm smaller)

- Nozzle temperatures between 180°C and 215°C

- Bed temperatures between room temp. and 80°C

- Flowrates 85% of actual flowrate up to 105%

- Printing speeds of 30mm/s to 80mm/s

- Different location on the buildplate in case that parts of the rail are worn out

- Cooling fan active all the time, off all the time, off for the first layers

- Checked bed leveling

- Checked extrusion -Variations of all of these things

It is noticable that the first few lines are layed down perfectly but when filling out the circles (in the case of these models) the layer becomes very rough. After that every new layer just suffers from the quality of the previous one. There is also a scratching sound when the nozzle moves over the object. I slice with Cura (latest version) and Z-hop is active.

I also checked the Z-rod and it at least looks fine to me.

I am really running out of ideas. I even checked every screw on the printer (and found out that the x-Rail wasn't perfectly straight but that didnt fix it either).

This problem occured after I replaced the entire print head with a new one since the old one kept clogging.