So, the wife got me a Creality Ender-3 Pro 3d Printer for Christmas.

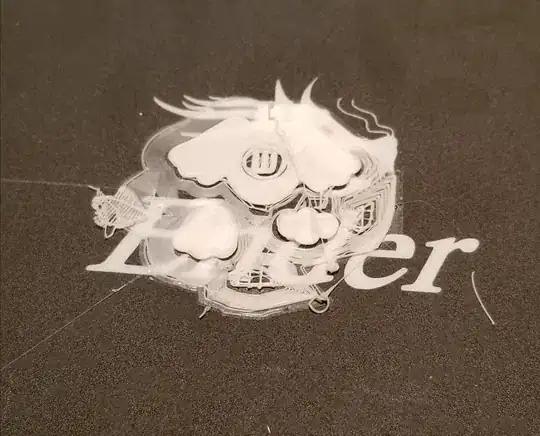

Assembly was easy, axis movements are all solid... when I go to print the test-dog.gcode file provided with the machine, it comes out looking... flat.

Not kind of flat. TOTALLY flat.

The Z-Axis motor works - I can move it with the machine's control panel - and it moves on it's own for repositioning of the head for printing purposes, but it doesn't seem to be moving 'up' for each new layer. Layer height is set for 0.1 mm, nozzle is .4 mm. No settings changed in the G-code, or on the machine (and I did a "reset to failsafe" before attempting to print anything).

I'm relatively new to additive manufacturing, can someone help out here?