First things first:

Don't Panic

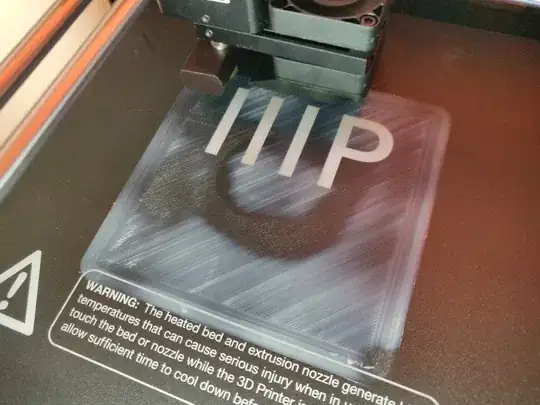

Your heated bed is made from metal with some sort of Build-Tak-Clone surface. It is not broken from what I can see. Your print is not failed, however, the quality does suffer a little bit.

Your bed does warp a little under heating. That is perfectly normal, and you should actually calibrate your layer thickness against a hot heatbed, not a cold one as metal that is heatbed extends - especially over the heating elements. The main heating element is usually in the center, so it "bulges" a little there, and if the heat has not equalized everywhere, it can show a dimple around it. So it warps slightly. The extent of the warping is determined by a couple factors, but from what your print looks like, it is not in a worrisome amount - the second and third layers will even it out.

I can't tell how much time passed between reaching the print temperature of the bed and the start of the print, but you might want to make sure the heating behavior heats the bed first and the hotend second, allowing the heat energy in the bed to spread more evenly. A tiny G4 P20000 ; wait 20 seconds (see here)` in the pre-print code, before cleaning & priming the nozzle might also help.

You can try to get more even first layers by positioning the parts in areas that do not suffer from warping.

As Tom mentioned, you might get better base layers if you increase the first layer thickness. I usually print with about 0.15 to 0.2 mm for the first layer, regardless of the following layer thickness to even out small miscalibrations and unevenness in the heating.