I am currently encountering a problem where under certain circumstances, the extruder stutters when it starts a new layer. I am printing on an Anycubic i3 Mega and am slicing with Cura 3.6.0. The problem seems to occur in the main part of prints, as well as in supports. However it seems to only occur after a retraction has taken place. I have taken a video of the stuttering which can be found here: https://photos.app.goo.gl/G3TLKveMsLNRQmgv7

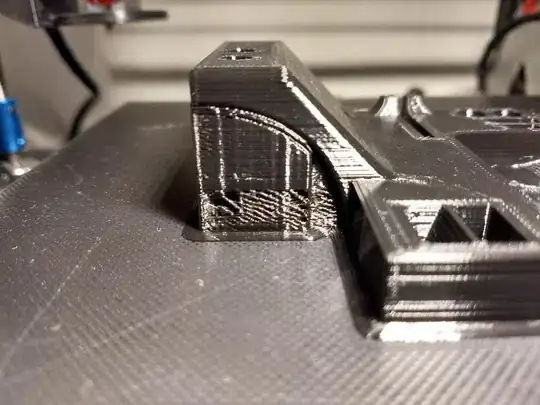

When a print is done the stuttering results in walls looking like this:

Can anyone help me figure out what is causing the stuttering?

Thank you very much!

Can anyone help me figure out what is causing the stuttering?

Thank you very much!

-

Welcome to 3DPrinting.SE! – Pᴀᴜʟsᴛᴇʀ2 Nov 24 '18 at 19:07

2 Answers

You retraction settings may be too high. Direct drive extruders require less retraction than Bowden style extruders. Typical retraction settings for direct drive are 1.5mm at 50mm/s and for Bowden, 4mm at 50mm/s. The speed usually makes more of a difference than distance beyond a certain point.

You can get away with smaller retraction settings if you increase travel speed because there will be less time to ooze. You could also try using Coasting as well.

Anyway, try reducing your retraction settings if they're higher than what I stated above. Another alternative is to set an extra prime distance so that extra filament is extruded after the retraction.

- 143

- 3

Definition: Sparse layer fill (called stuttering by the OP)

Why a sparsely filled support structure... (at the support bottom)

Support structures are added by Ultimaker Cura as the first part of the layer before it progresses to the rest of the print object. The bottom part of the support structure is definitely showing under extrusion, as if there was not enough filament available to print the support solidly. Actually, that is exactly what is the problem, there is not enough filament available for printing as a result of a retraction and the following extrusion after movement of the filament. The bottom part of the support is most probably printed after the head stopped far from the support (end of the previous layer) while printing your object. This means that the filament needs to be retracted, the head moved to the support structure, filament extruded (de-retracted) and printing of the support structure starting. When retraction is not optimally tuned, the nozzle may not be primed correctly with filament and cause a sparsely printed support structure. A similar reasoning could apply to support structures being printed at the final stage of the layer (as long as there are large movements to the support structure requiring the activation of the retraction).

Why is the support better printed higher up...

You see that when Z advances above the thickness of the right part of the print, the support structure is better printed. This could be caused by the fact that the head now doesn't need to move far from the last position of the print to the support structure, this doesn't require a retraction action.

What to do to print better support structures...

Try tune your retraction settings, see e.g. this answer shows an image of a calibration print to determine the optimal settings.

Note that you not only can play with the filament retraction settings (Enable Retraction, Retraction Speed and Retraction Distance), the option called Enable Coasting and Coasting Volume can also be used to stop extruding while the printer head prints the rest of the object to use the over-pressure of the molten filament in the nozzle and finally Retraction Extra Prime Amount can extrude some extra filament to prime the nozzle with some extra material so that the nozzle is optimally filled and ready for printing the support after the main print object. Also take care choosing the right Support Speed, too fast will result in lower quality.