Please note that the problems you faced are typical for the Anet A8, the connectors are underrated for the application. Also, do note that the stock firmware does not have thermal runaway protection, which is considered to be very unsafe and could potentially lead to burning down your house! Please flash a firmware that supports thermal runaway protection, like e.g. Marlin Firmware.

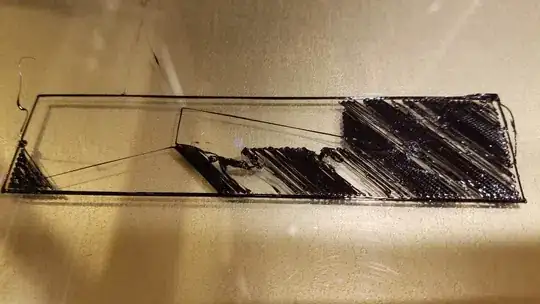

Basically you just tried to change some parameters to see if they have an effect. This is generally a good idea to get an idea of the problem, but a more technical approach would be to start from the beginning and exclude things you have tested. As for now you cannot conclude why the print looks as shown in the image, e.g. it also looks as if the nozzle to bed distance is too large.

The question remains if your 3D printer board did survive the shorting of the hotbed leads!

To troubleshoot this particular problem it is advised to check whether the extrusion process still does what it is asked to do. Disconnecting the hotend from the extruder and measuring how much filament is extruded would be the first thing to check. Please look into How do I calibrate the extruder of my printer?. It seems odd that the extrusion is off if the firmware has not changed, or alternative settings stored, but to be sure it would be the first thing to check. From this exercise you'll learn whether the firmware is set correctly and the extruder working properly. It can still be that the extruder gear slips, e.g. because the filament does not have a lot of friction when disconnected from the hotend.

When the extrusion process works and the commanded length is extruded, you can update the question with what you have done. After this, and if the problem persists, you can look into nozzle clogging and filament resistance for instance.