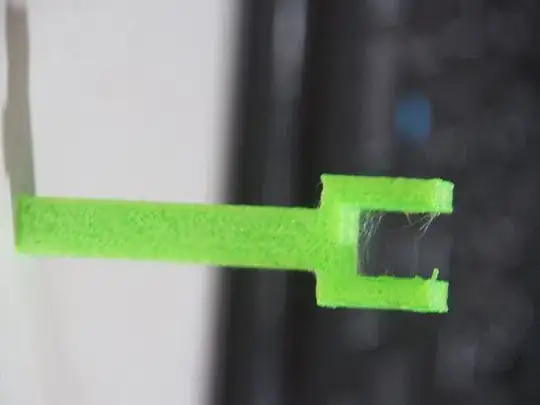

This effect you see is called stringing. Stringing can be reduced by changing any or a combination of the following slicer settings:

- lowering hot-end temperature, (less heat means less heat input so less runny filament oozing out),

- increasing travel speed, (increase in travel speed reduces the time to move to another point implying less filament oozing),

- retraction, (increased filament retraction reduces the pressure build-up in the hot-end decreasing the filament oozing)

- increasing coasting length (coasting means that you stop extruding filament prior to a move when the head is still printing, this is explained by the pressure build-up in the hot-end; ideally you set the coasting length as such that all the material that is pressed out as a result of the pressure build-up is extruded just before the head moves/travels to another location),

- print part cooling, (see this topic)

In order to find the correct settings you will need to print so called calibration test prints. There are a lot to find on Thingiverse, just search for "stringing".

Your print temperature may be a bit high, but some PLA filament brands require that, I don't know if that is the case with your filament, but you could start try lowering that by 5 °C a time.