Really strange observation with my MP Select Mini V2 printing PLA. I've printed a dual-fan shroud so I can have a dedicated part-cooling fan. I've noticed that when I turn it on, the extruder starts stringing everywhere. Little tiny spider-web wisps. No amount of temperature change will make them go away (printing at 200 °C). But if I simply turn off the part-cooling fan, I get a perfect print. This doesn't make sense to me - isn't the part-cooling fan supposed to reduce stringing by cooling the filament faster?

More info: Using Ultimaker Cura 3.4.1, retraction enabled at 3.5 mm and 40 mm/s, which works great when the part-cooling fan is OFF. But when I turn it on without changing any other settings, I get stringing everywhere.

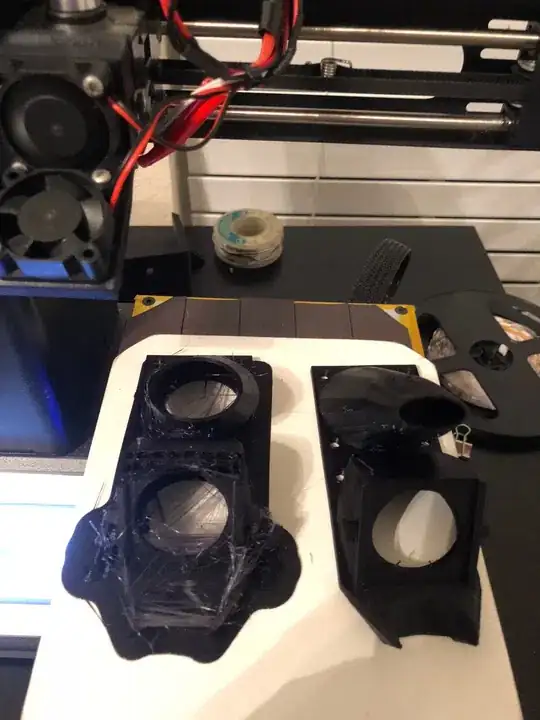

Please see picture below. The part on the left was printed using the part-cooling fan and the one on the right was printed without the part-cooling fan. No other changes. The part-cooling fan is pictured in upper left (bottom fan).

Why does my part-cooling fan cause stringing?

Note that I print at 0.175 mm layer height, or "Normal" for the MP Mini. The cooling fan can be controlled but if I turn it completely off then the cold end part of the nozzle won't get actively cooled. Using Cura I can slowly increase the fan over the first several levels as well, but I'm worried that if the cold end doesn't stay cold it will get clogged up with melted filament. I will try some different fan speed settings and report back - currently running at 100 % all the time.

I went back to the stock shroud with single fan to remove variables. The stock shroud has a small vent at the bottom where air blows over the part, but not much. I had the same problem - I had to put a piece of tape over the blow hole to get the part to print without strings. I also couldn't get the PLA to stick to the bed easily when the blow hole was open. I'm not using the heated bed in any cases - I've found I can print most PLA without heating the bed at all. I'm beginning to think maybe this PLA is just extremely temperature sensitive. The brand is 3D Solutech Printer Filament Real Black.