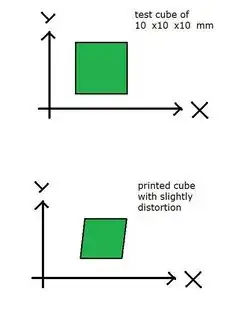

I have a Tronxy X5S and I am having issues calibrating my X and Y axis. When I print a 20 mm3 cube it comes out 19.9 mm x 20.4 mm x 20 mm. I have already made the belt tensions as even as I can get them but it did not change the calibration cube size.

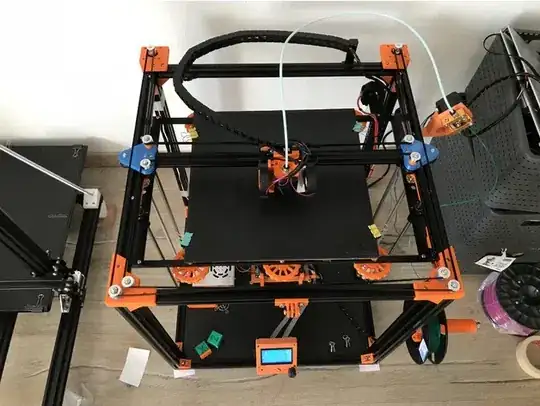

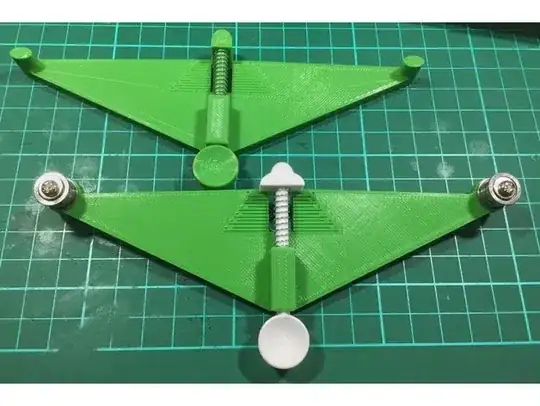

I have added this upgrade to my printer for the idlers and motor mounts:

I have also upgraded the hotend to a V6 clone, after this change is when I noticed the discrepancy in the calibration print.

What else can cause the X and Y axis to be uneven in a CoreXY printer besides uneven tension in the belts?

UPDATE:

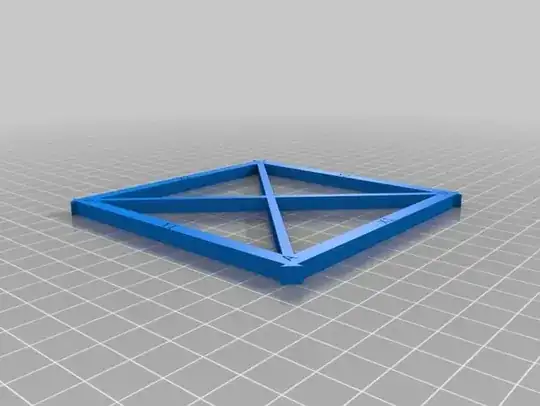

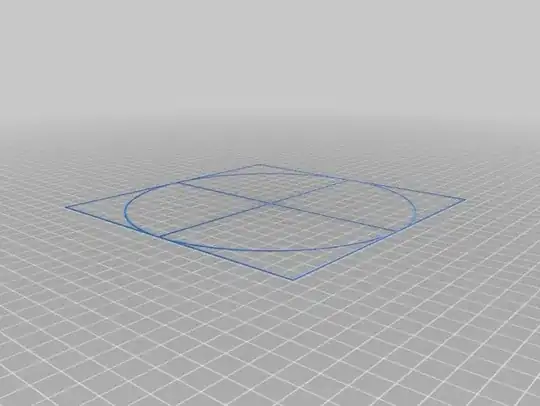

Its seems Oscar was correct in his assessment that my printer is not printing square. I printed this calibration square to measure the diagonals and I got: $ \overline{AC} = 141.82 $, $ \overline{BD} = 141.35 $. I believe the correct value for these diagonals should be $ \sqrt{2} \times 100 \approx 141.42 $.

Oscar also mentioned that I can adjust my firmware to correct this but I would rather fix the problem than apply a band-aid. Does this indicate that I did not assemble the printer frame correctly?