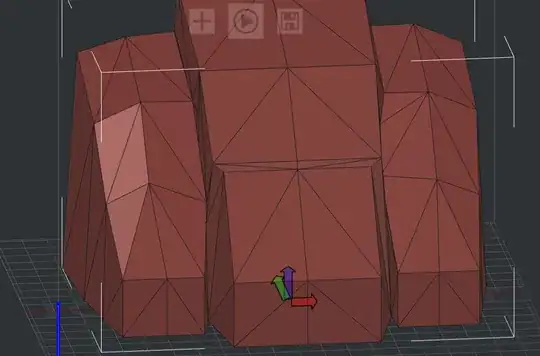

I'm trying to print a model that looks like this:

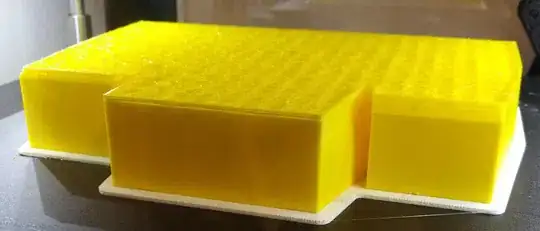

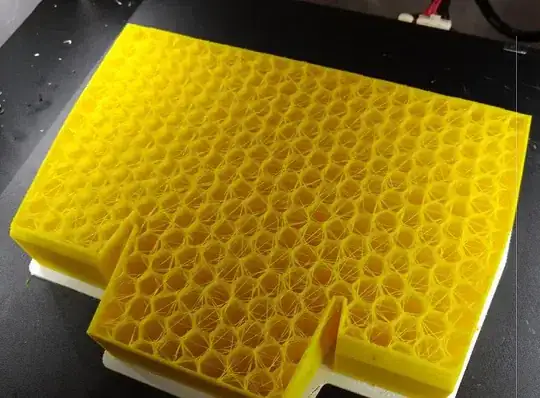

at a size of approximately 10"x7"x7". I've tried 3 times now, with various different infill and shell settings, and had it fail all 3 times in the same way at the same point: right at the point where the central column begins to angle back (which is a bit higher than where the two side columns angle back--those angles print just fine) the whole thing ends up detached somehow and I end up with messes like this:

How can I figure out what's going wrong with this print? I've already wasted a non-trivial amount of time and filament on this, and it's starting to drive me up the wall. Somehow, I've got the wrong settings to make this geometry print, but I can't seem to find any settings that actually work.

Using the Raise3D N2 Plus dual-extruder printer.

EDIT: WRT questions raised in the comments:

The extruder isn't clogging. It's continuing to print; it's just that at the point where the central column angles back, the whole thing separates and I end up with a distinct layer that prints straight up and down rather than angling inward.

I'm using PLA at 215°C and 3 wall layers.

This problem seems to be specific to this model; I've been able to print other large things before without problems.

Never heard of MeshMixer, but the reviews on the download page make it appear to be a very buggy and wouldn't work at all, at least in the current version, and it requires a registration to download even though it's nominally free, so I think I'll pass on this one.