I've just purchased an Alladinbox SkyCube 3D that I want to use to print board game miniatures and other fun stuff.

However, the instructions do not give the settings I need to put into software like Ultimaker Cura, and this is where I need some help so that I can generate the G-code files from models I download from MyMiniFactory.

I know it uses PLA and the extrusion temperature should be 210°C. However, I need help with the other settings.

Can someone please point me in the right direction? Is there a better software I could be using? Where can I find settings?

Thanks.

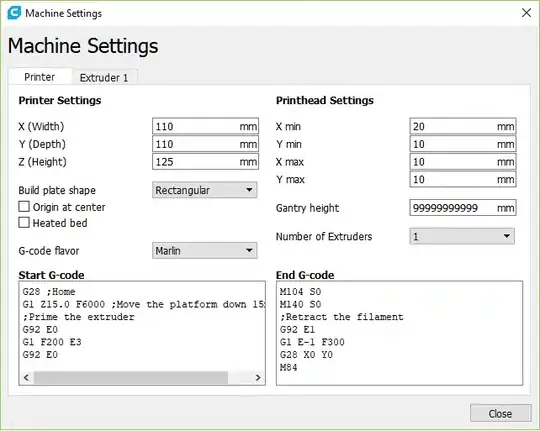

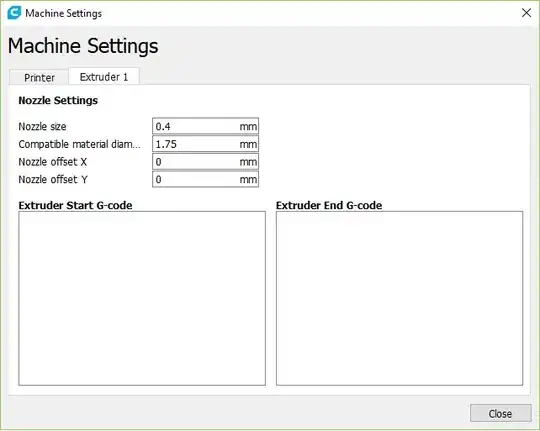

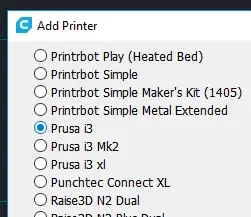

UPDATE: For those wondering "what" settings, I would probably start with the printer and extruder specifications. The following is my best guess.

and

I'm basing these settings on the device specs on this page: Link to Alladinbox specs