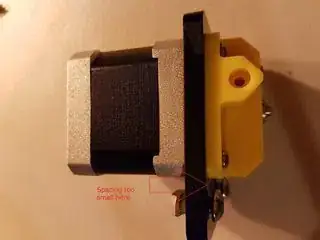

Your request appears to be "another set of eyes" and I'll add to that by adding another photo:

If you compare the photo from the official store you can see the gap between the mounting screw and the body of the extruder assembly is obviously wider in the official photo. On the plus side, the extruder mount is not something that would be considered system critical, because you're using a Bowden tube design. Even a bit of misalignment would mean zero impact on the printed model quality.

Consider to contact the seller, including the photo from the store and your photo and ask for a correct mounting plate. You would likely be able to use the oversize hole mount until a replacement arrives. For such a small part, they should not charge you.