If you look closely at the slicer output, you will probably see that these regions just have outer shells, and no infill. What is happening here is that the part thickness is between 2 and 3 nozzle widths (or possibly between 4 and 5). If you ask for a 1 mm thickness, but only have a 0.4 mm nozzle, it is not easy for the slicer to split this into 2.5 passes.

One thing I found would sometimes help is to change the nozzle width setting in the slicer (to maybe 0.39 mm) and this sometimes helps (at the expense of needing to offset the extrusion rate to compensate).

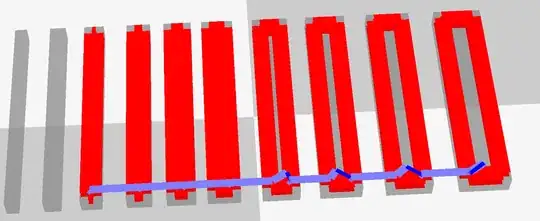

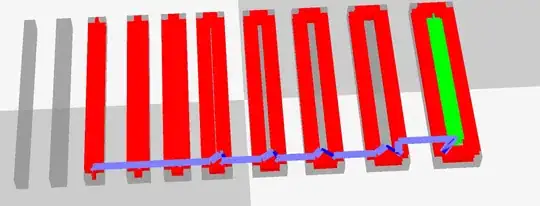

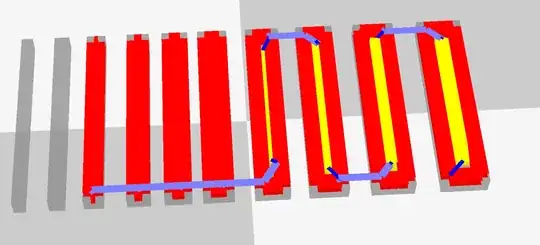

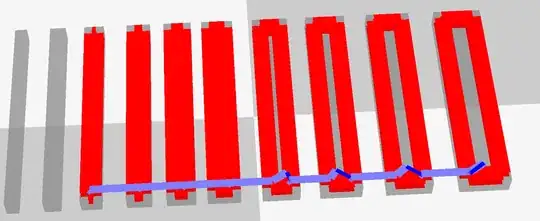

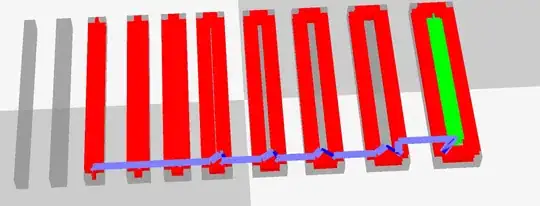

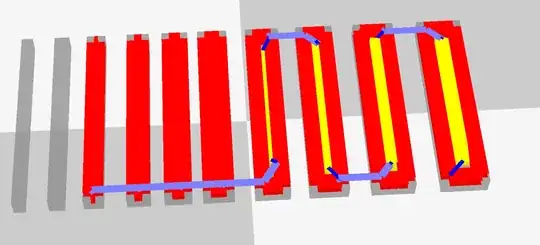

Here are some rectangles of width 0.3 mm to 1.2 mm (increments of 0.1 mm) sliced in Cura 2.31. The first is 'normal', with wall count set to 2. Next is an inaccurate (small) nozzle setting of 0.38 mm, and finally the correct 0.4 mm nozzle, wall thickness of 1. The last setting shows infill (in yellow) rather than an inner wall (green).

Normal has a gap in anything over 0.8 mm wide.

Normal has a gap in anything over 0.8 mm wide.

If I reduce the nozzle width, I do get some inner walls, but only where there was already space for 2 walls.

When I only request one wall, the rest infill, (even though I have 20% infill), then the result is as expected. This seems to be a bug in Cura (or at least something which is improved in the version currently in beta).

There is a bit more detail in this question Missing top layers in Cura