I received a Monoprice Maker Select v2 (I3 V2 clone) from my wife for Christmas. The sample .gcode files that came with the printer generally print great with no noticeable defects.

However, when I try to print miniatures for use with table-top gaming (D&D, primarily), I tend to get a lot of oozing and stringing. On top of that, bridge supports don't cool in time and tend to get fudged by the print nozzle, which results in oddities like arms being only half printed, sticking to the nozzle, and getting relocated to some other part of the print. If I use full grid supports with the most modest fill settings (8%) they end up being stronger than the miniature and are a real pain to remove.

My printer is calibrated, as level as can be (the desk it's on is slightly warped but I've got the printer in the center of the warp; there is no wobble or lean) and squared. The build plate is calibrated and set to the right height.

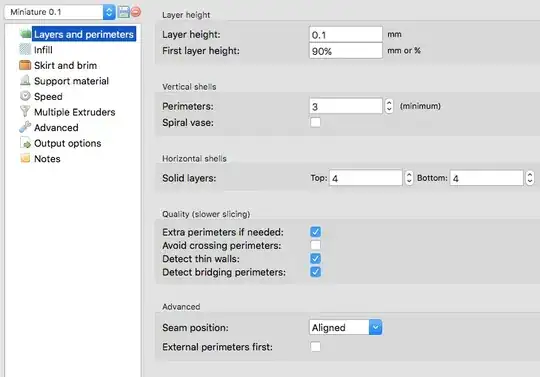

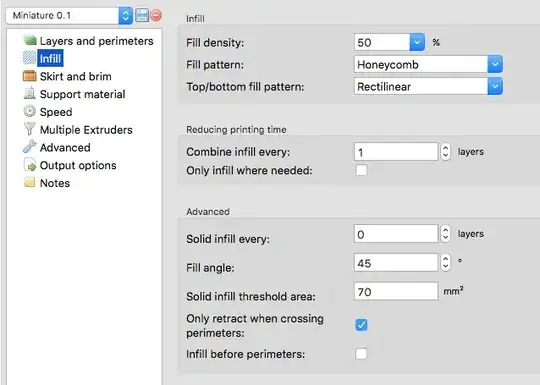

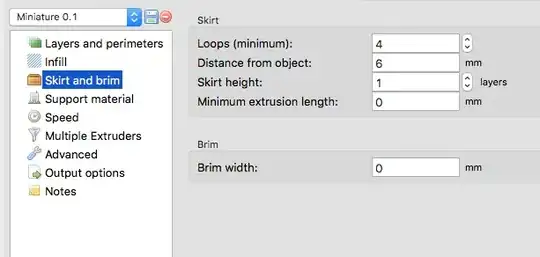

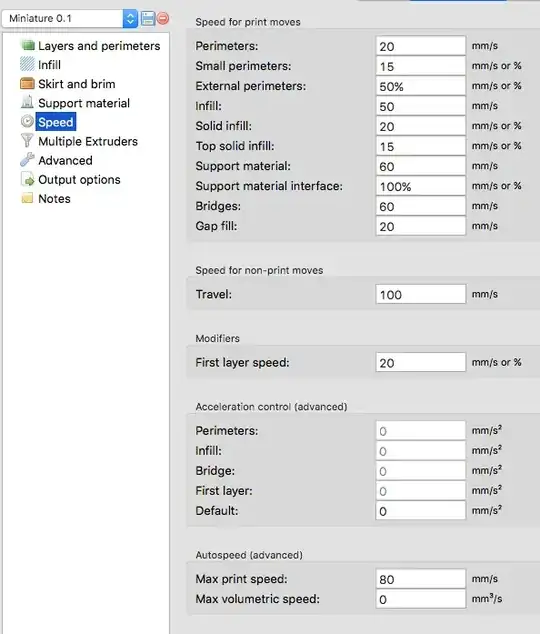

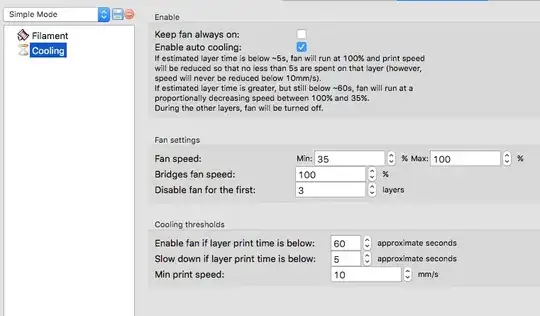

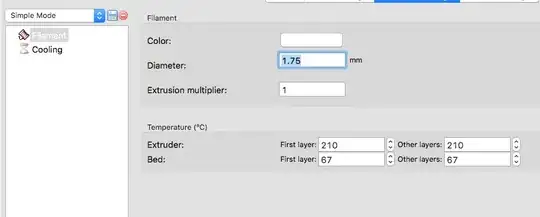

I'm using the version of Cura that came on the SD card with the printer (honestly not sure which one and I'm not at home to check). I've fiddled with print speed, extruder temp (ranging from 185 to 210), layer cooling, retraction settings, and tried switching to Slic3r (didn't go over well -- couldn't even get past the first layer).

I'm using Hatchbox silver PLA filament (1.75mm +/- 0.05mm). I don't have another filament I can test with to compare performance.

Even when I import the profile settings from one of the sample .gcode files I tend to end up with blobbing, pulling, and stringing all over the miniatures, in addition to missing or deformed parts. Notably, arms and hands -- most often overhangs -- tend to stick to the hotend and get repositioned, sending the whole thing out of whack.

I end up with similar problems when I use the Novice mode settings in Cura (Normal Quality, High Quality, etc).

Is there something I'm missing that I can do to improve the quality of small, detailed prints, or is the I3, as an entry-level printer, simply not up to the task? I'm especially interested in answers from users who have experience printing miniatures and their experiences in tuning for that type of print job.

A few things I've tried test printing:

Printer calibration test model v1

Printer calibration test model v3

Both of these came out very stringy, with lots of blobbing and layer pulling, especially towards the upper portions of the taller elements.

I have also tried printing these two models:

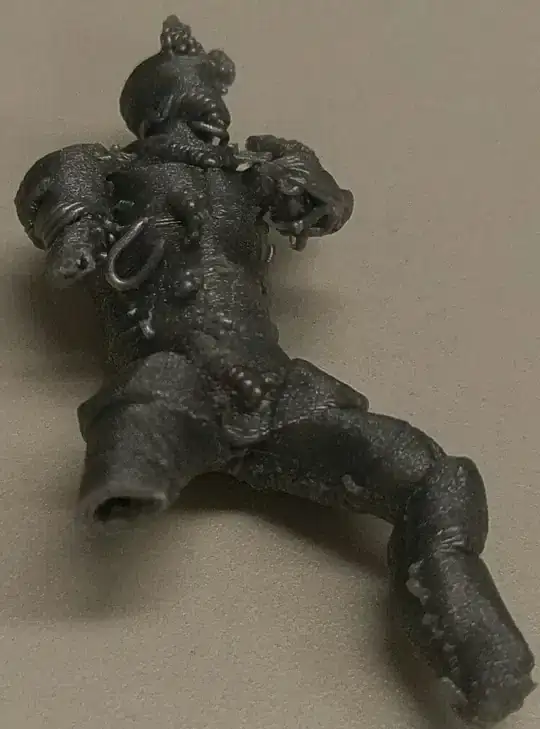

Knight with sword - high detail

All test prints of these two models had at least one missing hand due to it getting stuck to the hotend and pulling off the part, and both demonstrated lots of minor blobbing and pulling on otherwise smooth surfaces, with loss of detail in the more finely detailed areas. Here's a sample of the output for the knight model. Please ignore the fact that he has been dismembered, that was mostly my fiddling with it post-printing (I guess I don't know my own strength), though the left hand was not well-attached and fell off rather easily. He was printed with both hands and feet/base intact, but you can see the blobbing and pulling pretty well.