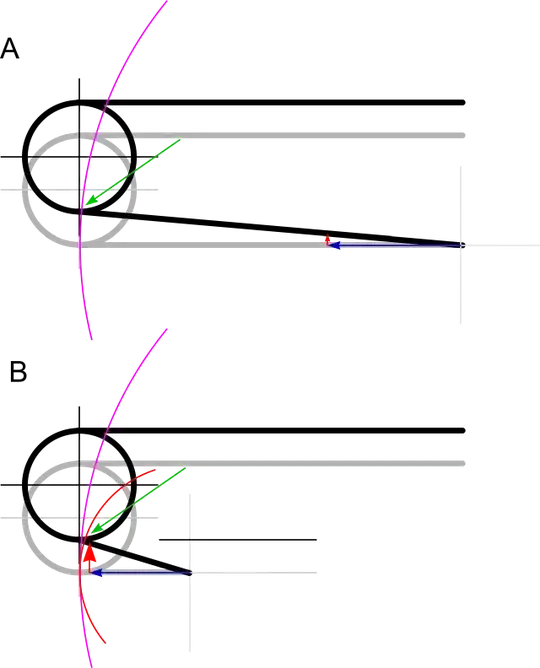

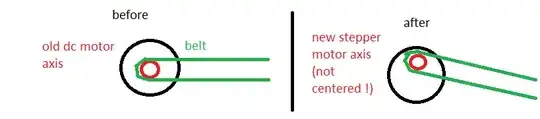

I'm currently attempting to make a repstrap using paper printed parts, like this guy : http://www.mariolukas.de/2012/05/repstrap-3d-drucker-aus-computerschrott-teil-1/ I replaced the DC motor in a paper printer carriage assembly

with a stepper motor (NEMA17). But there was not enough space to fit the axis of the nema 17 at the exact spot of the older DC motor axis, in short, the axis are not in the same place. The question is : if the axis is not in the exact same spot, will it affect the movement of the carriage or not at all ?

I supposed it would but i'm not sure since the carriage is limited in movement by the rails and that we still move the belt around.