I'm having some problem with my Ender 3. I have been printing for almost a year with good results. Then, all of a sudden, the fan started to be noisy and the prints came out definitely not good.

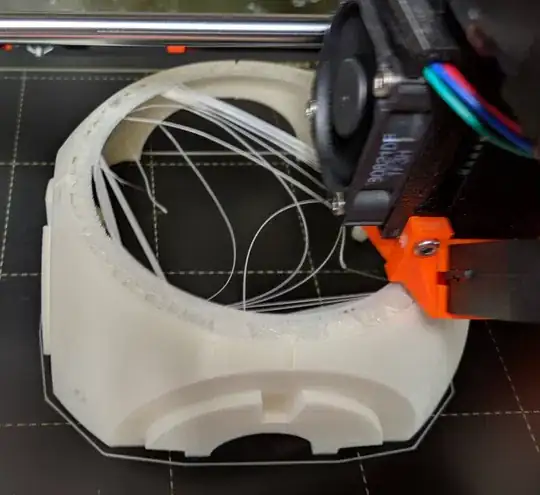

From what I understood looking around, the problem could be under extrusion.

I replaced the fan (both of them actually) but the prints keep coming out badly. The software is always the same (Cura) and I never changed any parameter whatsoever.

This is what I tried so far:

- printing with (four) different filaments (always PLA though).

- changing the E-steps

- unclogging and replacing the nozzle (twice)

- re-calibrating Z like a million times

- printing different projects, included those who I already successfully printed before

-> Nothing helped!

Then I was forced to also change the software (because my PC died...) But even with the new version nothing changed. Now the extruder calibration is okay (I print 10 cm and 10 cm of filament are consumed through a hot nozzle).

Increasing the flow by 5 % and the temperature by 10 °C (I'm now printing at 220 °C....) actually gives better results (the calibration cube is more definite and more solid) even if under extrusion is still appreciable.

I don't know what else to try!!! Can someone help me?