Outer wall perimeters are printed as continuous lines, unless the geometry determines otherwise.

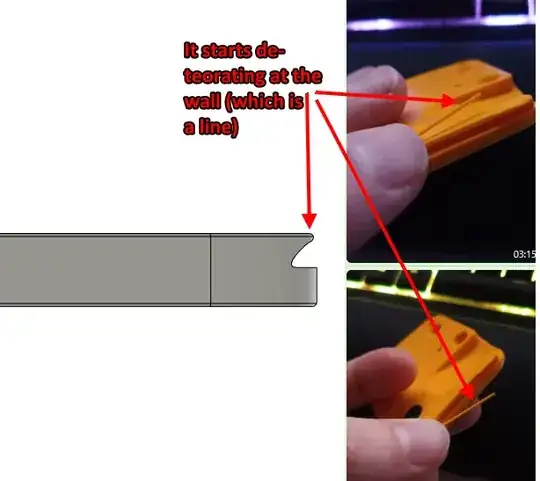

Your print faces an overhang situation in which it is prone to print walls from the inside out as where it sticking the wall lines together.

Default behavior is printing the outer wall first and traversing inwards, in overhang situations this isn't ideal so that you may want to print the wall perimeters inside out as if you stick the newly deposited perimeter to the latter.

Generally, printing outer perimeter first will give the print better dimensional precision, but, may cause problems in overhang situations where there is limited area to "stitch" your perimeter to, hence the poor adhesion you experience.

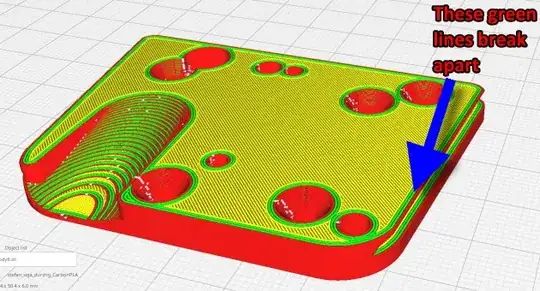

A solution is to print inside perimeters first and work outwards, in Cura, there is an option for called Wall ordering to change the order of perimeter printing.

After updating your question with the print speeds, another possibility that came to mind is that you are extruding too fast for PETG for your setup (extruder and nozzle assembly). Not all extruders can process PETG fast enough or nozzle assemblies cannot heat fast enough causing the nozzle to under-extrude. I've seen this happen on my own printers. Please note that the premium brand I use, limits extrusion to 50 mm/s, 80 mm/s might be on the high side for your setup. It isn't that PETG cannot be extruded fast, it is merely that not all extruders and nozzles are capable of doing so (especially the lower end of the 3D printer market). So even that you now can stick perimeter from changing the order, under-extrusion might prevent from a good adhesion.