I have an Ender 3 Pro modded with the Hero Me Gen 6 air ducts, installed a Creality 4.2.7 mainboard, and updated Marlin firmware to the latest for now 2.1.1 version. I'm printing with PLA only.

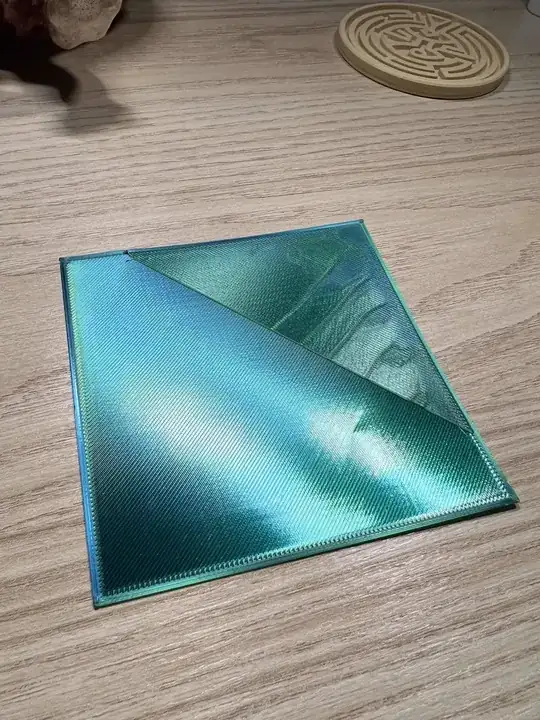

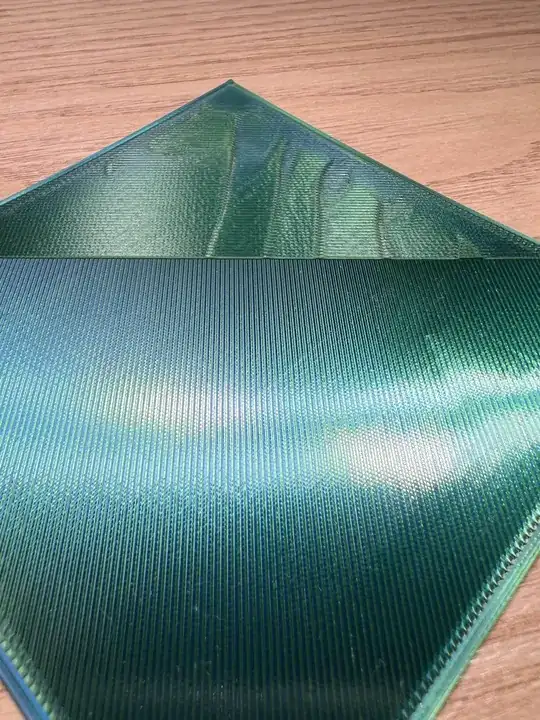

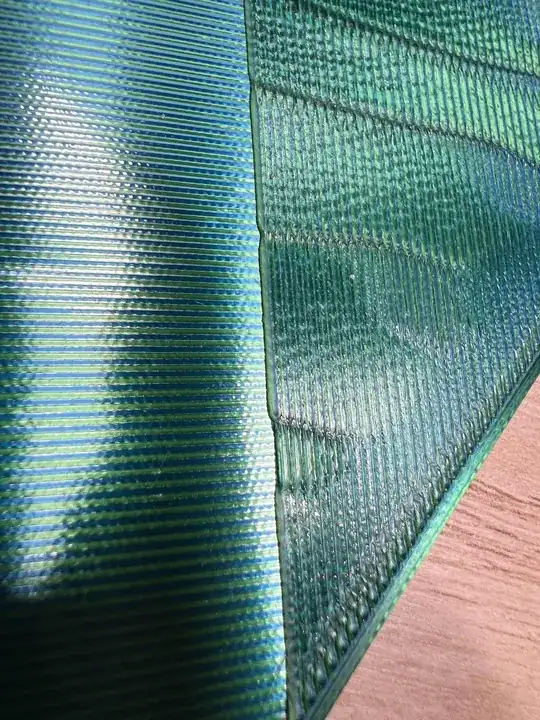

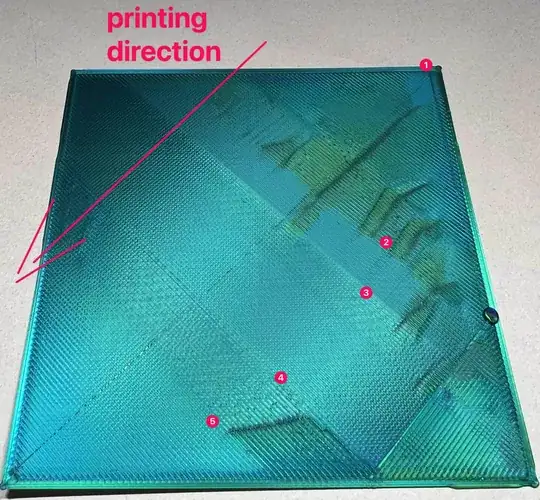

It was printing well enough. The nozzle started to wear down so I replaced the nozzle (standard brass one) but also upgraded the heatbreak to a bi-metal one (not all-metal, there is still a plastic tube inside the heatbreak) and a heatblock (standard goldish Creality block). And since that moment, the printer fails to print with good quality starting the second layer

What I tried:

- recalibrated it with a gauge of 0.2 mm and the first layer is perfect (did not know that could be a thing :))

- updated firmware

- tried to tighten screws (as it is recommended here)

- adjusted Z-axis steps/mm

- another filament

I can't figure out what causes that thing.

edited 2022-10-25 23:41

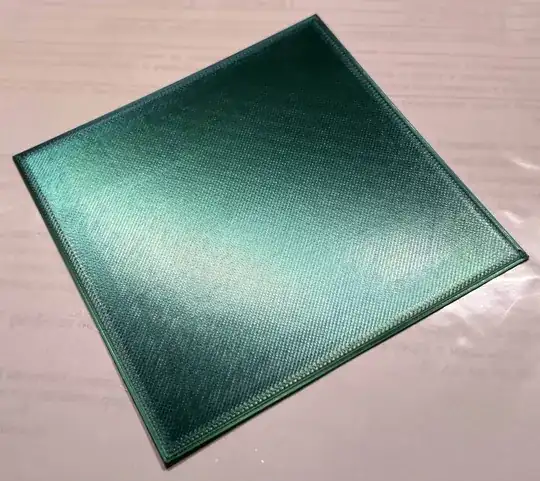

I think it is overextrusion. I tried reprinting object. The first layer was perfect, but second was poor again. There was no difference with cooling or without, no difference printing slower. But flow rate did matter:

- 100% flow rate

- changed to 85% flow rate

- changed to 75% flow rate

- changed to 100% flow rate

- changed to 75% flow rate

Maybe it is prusa slicer doing its thing. I will try Cura. The only thing that bothers me is that diagonal scratch - that is from the nozzle which makes me think it is too low for the second layer

edited 2022-10-28 15:53

It's not a slicer thing. I sliced object with Cura and got pretty much the same result. I babystepped z-axis during the print to get nice result. So I think it is either z-axis motor not stepping enough or I need to lower extrusion multiplier in slicer. I will print calibration cube to check if z-axis motor steps up enough

edited 2022-10-28 18:34

Printed calibration cube. Turns out my z-axis steps were off. Model was 19.66mm instead of 20mm. I tuned steps to 407 from 400. That helped a bit (model is 20.02mm now) , but still the same ugly overextruded result. Tried to lower extrusion multiplier to 0.8 and still got the same bad result

edited 2022-10-30 22:11

It is neither nozzle nor heatbreak tube. I checked it using my old hardware. Maybe it is somehow connected to firmware... Or E-steps are off while printing