FEPs are consumables

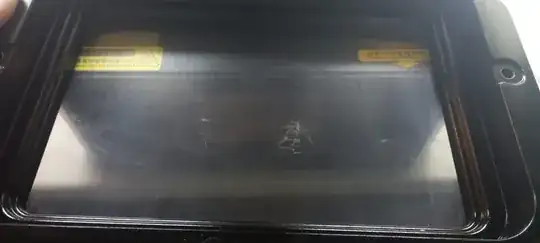

Once an FEP film on the foil has developed cracking, it's a lost cause and has to be replaced in due time - repair to pre-damage conditions is impossible even if you manufacture them.

You can try to avoid the affected areas and eek a few more prints out of the film, but the damage will spread and make the film unusable in the longer term.

Damage to FEP can occur due to bad resin

If your resin contains any chunks due to print failure, those can result in damage of the FEP.

Bad Placement and high speed can damage FEPS

Another reason can be too pointed pressure, which happens for example if the only spot is pulling up very high, and then suddenly releases.

The position of the printed objects can be as much the factor in this case as the size or geometry of the release area.

The more controllable factors that play into this are the lifting speed and height of the bed. It takes some non-zero amount of time for the film to release the model. During this time the film adheres to the model, and can be simulated as a spring. The force of a spring is dependent on a constant and its elongation: $F=k \times \Delta d(t) $. Our foil would have a variable factor $k$, dependent on the coordinate in the vat. However, for us, the elongation at the moment t $\Delta d(t)$ is relevant. By lifting faster and higher, the film is experiencing more elongation (stretch) and a sharper release from the model happens. Higher stress means damage to the film.