I recently tried to use Matterhackers Quantum filament and I've run into some issues and curious if anyone else has. I have a CR6-SE with community firmware, a regular Bowden tube with upgraded heatbreak (the metal tube that goes inside the heat block where the material is melted) installed, slicing software is Cura 15. My issue is I can't get it to print well or for long. I can run Polymaker, Geeektech, Sunlu, and most other brands of PLA without issue or minor tweaks. This stuff will not play nice. I'm at my wit's end trying to figure this out. Here are something's I've tried. The first 15 to 30 layers will go down beautifully and then it just stops extruding. When it starts to stop extruding it will print blobs all over the print surface, wispy lines, then nothing. If I am not there watching it, it will have layers of virtually very little filament like it was getting clogged up and the next layers after that will be normal.

I recently tried to use Matterhackers Quantum filament and I've run into some issues and curious if anyone else has. I have a CR6-SE with community firmware, a regular Bowden tube with upgraded heatbreak (the metal tube that goes inside the heat block where the material is melted) installed, slicing software is Cura 15. My issue is I can't get it to print well or for long. I can run Polymaker, Geeektech, Sunlu, and most other brands of PLA without issue or minor tweaks. This stuff will not play nice. I'm at my wit's end trying to figure this out. Here are something's I've tried. The first 15 to 30 layers will go down beautifully and then it just stops extruding. When it starts to stop extruding it will print blobs all over the print surface, wispy lines, then nothing. If I am not there watching it, it will have layers of virtually very little filament like it was getting clogged up and the next layers after that will be normal.

Other measures taken:

- Hot end temperature ranges 215 to 240 °C as per Matterhackers support instructions.

- Adjusting retraction distance/speed independent of each other.

- Adjusted heat bed ranges 40 to 70 °C.

- Adjusted print speeds 30 to 60 mm/s.

- Adjusting initial Z height from 0.15 to 0.2 mm.

- Put the filament in a food dehydrator for 2 to 48 hrs.

It's not just one particular file either; it's anything I try to print with this filament from a simple cube to complex curves and angles.

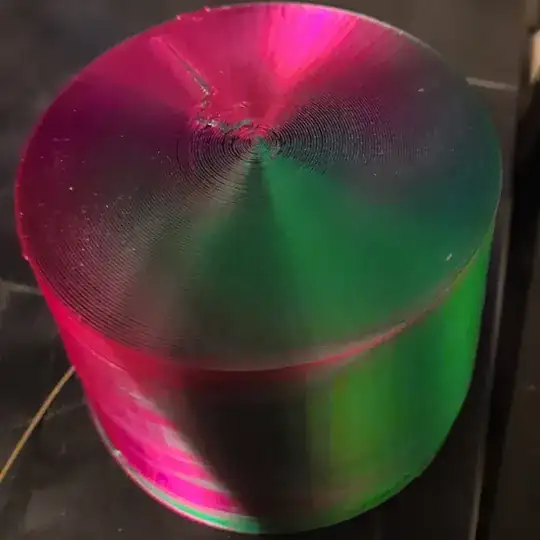

Image 1 shows first layer prints, these are mostly smooth and not problem with adhesion to the bed.

Image 2 shows how the print is changing. The temp has stayed constant throughout the entire print, but only towards the top is it smoothing out. On the bottom (pic doesn't show it clearly) there are layers missing, or partial layers missing.