I performed a polycarbonate modification on my Ender 3 Pro (heated chamber, external electronics, all-metal hotend, new thermistor, PID-tuning, dry-box, actively cooled motors through Peltier cooling, ABL leveling, polycarbonate printing surface, etc...). Basically, I did everything based on this:

Currently, the maximum possible temperature I can reach in the chamber according to my additionally added temp-sensor is about 65 °C. Near the printing bed, it could be a little bit warmer.

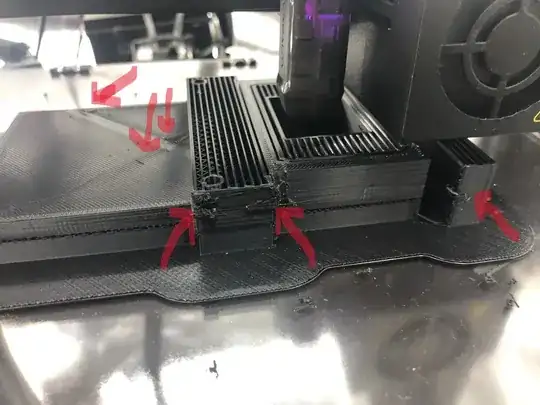

Please take a look at the following image of my current polycarbonate print. As you can see there is something wrong going on there, especially at the corners. I really don't have a clue what is causing these problems. Maybe you have more experience and some advice for me? (Please ignore the horizontal "Raft Air Gap" it is not a printing issue)

For detailed information regarding the pc-material take a look at the technical datasheet of the polycarbonate material:

- Nozzle: 250-270 °C

- Chamber: 70-80 °C recommended

- Build plate: 80-110 °C

PC from Raise3D Technical Datasheet

And these are my Cura settings:

- OS Windows 10.0.22000

- Cura Version 5.0.0-beta+1

- Material Extruder : 1 PC

Quality

- Layer Height 0.1 mm

Walls

- Wall Thickness 0.8 mm

- Wall Line Count 2

- Horizontal Expansion 0 mm

Top/Bottom

- Top/Bottom Thickness 0.6 mm

- Top Thickness 0.6 mm

- Top Layers 0

- Bottom Thickness 0.6 mm

- Bottom Layers 999999

- Initial Bottom Layers 999999

Infill

- Infill Density 100 %

- Infill Pattern Tri-Hexagon

Material

- Printing Temperature 265 °C

- Build Plate Temperature 100 °C

Speed

- Print Speed 50 mm/s

Travel

- Enable Retraction True

- Retraction Distance 1 mm

- Retraction Speed 20 mm/s

Cooling

- Enable Print Cooling False

Support

- Generate Support True

- Support Placement Everywhere

- Support Overhang Angle 63°

Build Plate Adhesion

- Build Plate Adhesion Type Raft

- Raft Air Gap 0.2 mm

Machine

- Machine Type Creality Ender-3 Pro

- MicroSwiss All-Metal Hotend (0.4 mm nozzle)