Looking up your printer, one thing I noticed is that it has power loss recovery. This feature writes to the SD card at the start of each new layer, stalling the print for at least a significant fraction of a second with the filament unretracted, which will make a nasty blob wherever the toolhead happens to be positioned. Absolutely turn this off. It's impossible to get quality prints with that feature on. If there's no menu option to turn it off, you'll have to rebuild the firmware or get alternate firmware from someone else.

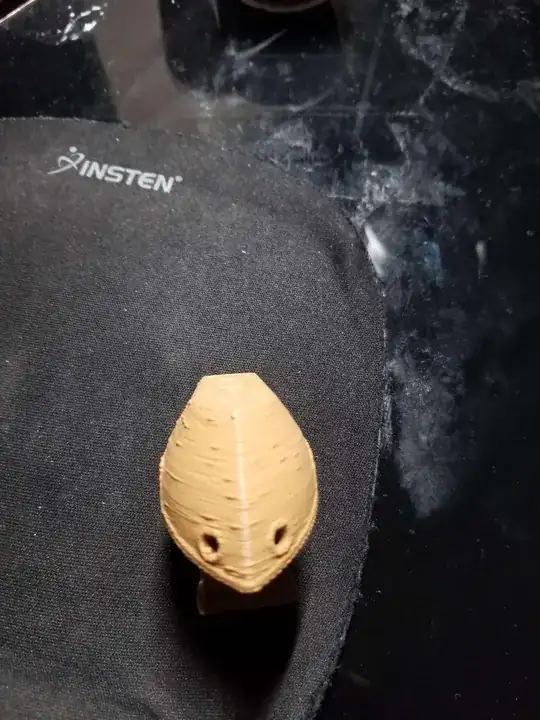

It looks like you have moderate overextrusion. If the esteps were tuned, you probably adjusted them too much in the direction to increase extrusion and should reset to the factory setting and calibrate again, erring on the side of less extrusion rather than more.

There are a number of places (especially on the cabin) where some walls are inset relative to where the wall was supposed to be, and where it's present in other layers. This is almost surely a result of losing material to oozing in the interior of the model, as a result of "combing". See this answer for details.

On the hull (especially the bow), it looks like you might be experiencing the consequences of numerical precision bugs in Cura, which result in erroneous tiny segments that break up smooth traversal of curves, leaving blobs where the toolhead stutters. Watch during printing and see if the nozzle is stuttering (suddenly slowing down then speeding up again) along these curves. If so, make sure the Maximum Resolution and Maximum Deviation settings are 0.5 and 0.025 respectively. These are the modern Cura defaults that avoid the problem, but some profiles (and some older versions of Cura) have values that trigger the bugs.