I am having two separate issues. One is specific to this particular model, the other is on all my prints, but more pronounced on 90° vertical walls.

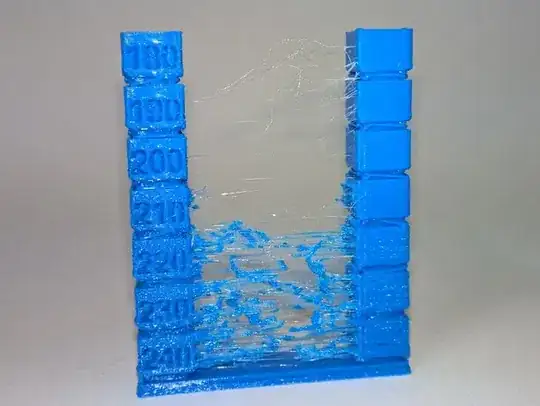

The first issue is a localized area of under extrusion only in one area of the print. This issue is specific to this model. The second issue is evenly spaced horizontal bulges that appear approximately every 5mm during the first 30-35 mm of the print. This is a two-piece Christmas tree I designed for my wife and I have been printing both pieces together on the build plate.

I am printing on a mostly stock Voxelab Aquila with Voxelab Gold 1.75 mm PLA. I have changed the stock extruder to the aluminum extruder after the plastic one cracked, and am running a Satsana style shroud with stock fans. I am using CHEP's Cura 4.11 Ender 3 profile for .2 mm (good) - CHEP Cura Profiles, printing at 200 °C and 40 °C bed temp. I have lubed my Z screw with white lithium grease, checked that belts are tight and no screws or physical connection points are loose. I checked to make sure that the eccentric nuts are snug but not binding the gantry. I have calibrated my extruder E-steps and changed the value to 96.

Can someone offer me some guidance on where to go from here?