I'm printing small detail on Prusa Mini with Prusament PLA @ default 215 °C.

Model was sliced with the PrusaSlicer with default 0.15 mm quality profile.

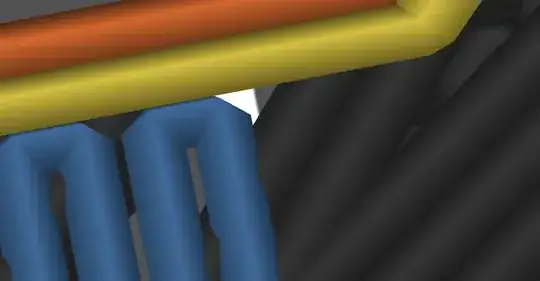

The problem is that when the printer is making the bridging infill it does not stick it properly to the perimeter layer. Making the place where head turned back hanging.

What may be the issue and how to prevent it?