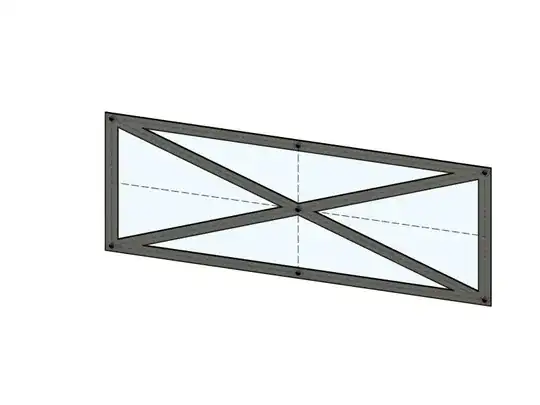

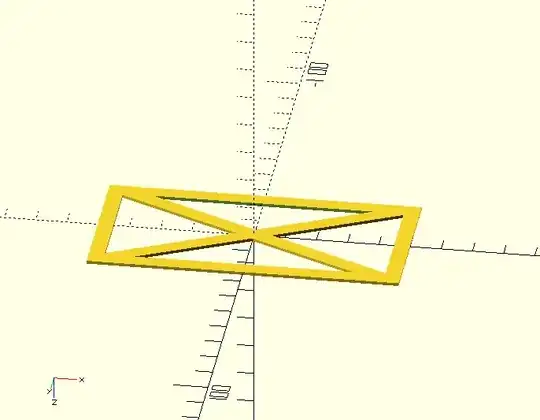

I'm trying to 3D print a lattice work or truss, basically some beams forming a rectangle and additional beams forming the diagonals and where those beams cross, they should be fused. So, something like this:

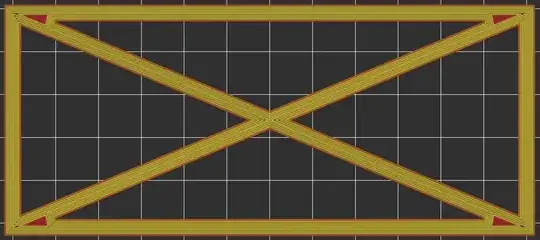

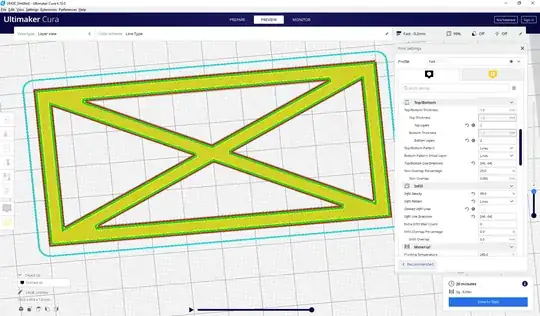

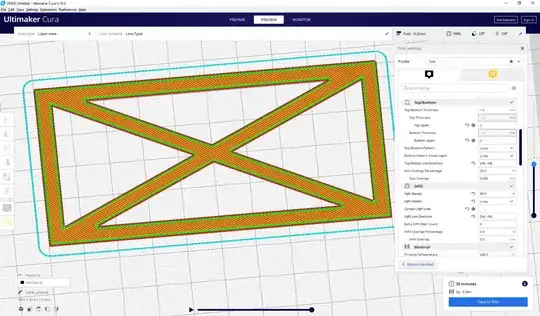

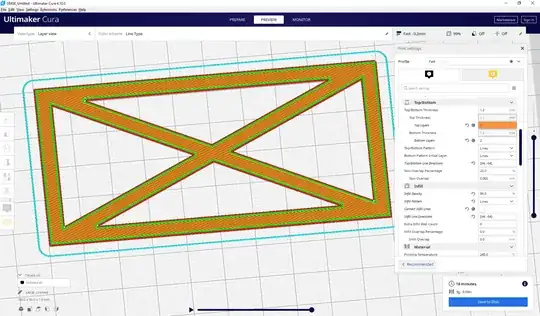

The problem is that any slicer I give a form like this to starts drawing triangles around the inner openings and in best case those triangles then touch if you use enough walls, but the pull strength you would get from beams in such a truss is lost because the opposite corners of the rectangle are not connected by a single length of filament laid down. Here as example what PrusaSlicer does for every layer:

Basically this gives separate triangles at the top, bottom, left and right with some rectangular walls at the outside. Not bad, but I think that for extra strength it would be better if on even layers there would be long extrusions going all the way from the top-left corner to the bottom-right corner (and hence interrupting extrusion on the other diagonal) and on odd layers having just the opposite (so long extrusions from bottom-left to top-right).

So, my question: is there any way to tell the slicer to do something like that? So, having extra long (alternating) corner to corner extrusions next to the triangular "outer" walls that it normally puts down? Or, is there some other trick I could use to get a similar effect (while also having long extrusions between adjacent corners)?