For some reason on my Raise 3D N2 plus with a Bondtech-Extruder I am sometimes seeing filament jams and sometimes it prints without any issues. I am using PLA at 215 °C.

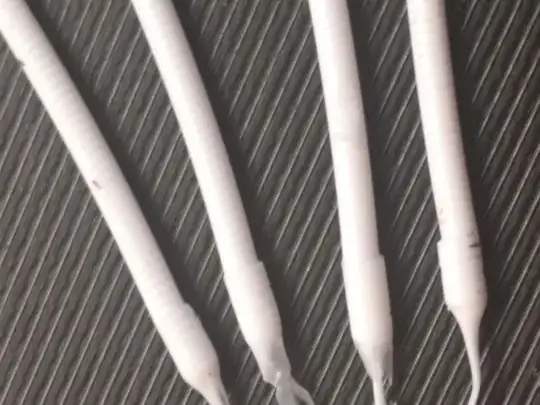

When the filament is jammed I have to pull it out, remove the tip, and then I can load again and everything works perfectly fine again. I have attached a picture of what I pull out of the extruder each time. It looks like the bottom part is some kind of skin of the filament.

It's hard to see but the tip of the filament is a little thicker, so it's possible that this can't be pushed into the extruder, but why would it build up there? I am using 3 mm retract, could that be the issue? Or is my extruder not hot enough?