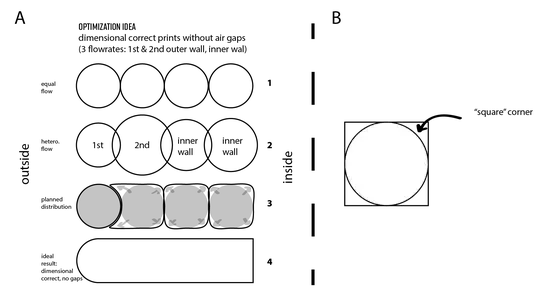

I mostly print mechanical parts and thus need dimensional accuracy. When calibrating my printer I stumbled over the fact, that some people calibrate flowrate with single wall prints which would give you a good measurement for your new flowrate. Doing this will on the other hand lead to underextrusion as you print perfect circular lines that only touch in a single point/line, leading in worst case to delamination. So you'd have to crank up the flowrate at least for the internal walls to fill out the "square"-corners (Cross section image B) you want to fill up as well. Doing this is already better, but could lead to a poorly connected outer wall to the rest of the print. Thus an idea (which isn't supported by Cura slicer):

For a dimensional print without air gaps, shouldn't the:

- 1st outer wall be printed to be the perfect diameter

- 2nd outer wall be printed with higher flowrate, to fill what the 1st is missing and fill up square corner

- rest of inner walls fill up the missing square corners

Probably the best fill up will be reached by printing the second outer wall after the outer and inner walls as it wouldn't go under the 1st walls cavity on its own.

Image (Simplified cross section of a single layer and its printed geometry):

- A1: Print with all the same flowrate, each line is printed with the nozzles diameter (Danger of delamination)

- A2: Print with 3 different flowrates. 1st outer wall with nozzle-sized lines. 2nd outer wall with highest flow to fill cavities under 1st OW and to fill up corners (air gaps), inner walls with medium flow to fill corners

- A3: ideal flow into corners and cavities

- A4: perfect result to aim for

Now some questions:

- Is this already possible with other slicers?

- Do you have done that and can share thoughts?

- Are there any drawbacks you see doing this?