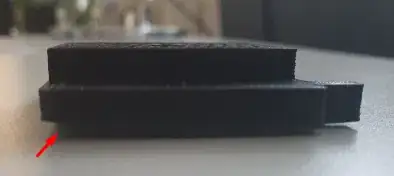

This is a very well known issue that is caused by insufficient adhesion. The corners curl up during printing.

You should increase the adhesion by:

- cleaning the bed (I use water and soap, others use isopropyl alcohol)

- better leveling,

- correct nozzle to build plate distance (dragging paper method),

- using a brim or so-called mouse ears in your design,

- increased the heated bed temperature, or

- use of an adhesive like hair spray or glue stick (not any type will work) or specific sprays that are created for this purpose (e.g. 3DLAC, Dimafix, etc.)

Some people used tape on the build plate for adhesion, but I'm not a fan of tape. Not all tapes work. Tape needs to be applied correctly, prepared (sanded), etc. This is much more cumbersome than applying a little spray over the build plate. It can be successfully used on PEI, Buildtak (clones), glass and on the bare aluminium bed.