The title pretty much sums up the issue. It was happening before moving to an SKR Mini E3 V1.2 and is still happening with the new board.

If I run A G28, then a G29 - while not heated - I will get some mesh data (poor mesh data because I haven't levelled the bed but that's not the main issue).

If I then repeatedly run G29 (lets say 5 times) there will be variation between the measurement but only and expected amount and nothing more.

Bilinear Leveling Grid:

0 1 2

0 +0.592 +0.270 +0.010

1 +0.082 +0.010 -0.062

2 +0.215 +0.078 -0.065

Bilinear Leveling Grid:

0 1 2

0 +0.597 +0.267 +0.002

1 +0.085 +0.007 -0.065

2 +0.215 +0.078 -0.065

Bilinear Leveling Grid:

0 1 2

0 +0.607 +0.267 -0.002

1 +0.085 +0.010 -0.065

2 +0.212 +0.075 -0.060

Although it does continue to climb a bit, it's a BLTouch they're not the most accurate things so I'm not worrying about it.

However, if I heat the nozzle (200 °C) and bed (60 °C):

Bilinear Leveling Grid:

0 1 2

0 +0.537 +0.252 +0.022

1 +0.057 -0.002 -0.050

2 +0.200 +0.075 -0.087

Bilinear Leveling Grid:

0 1 2

0 +0.495 +0.203 -0.030

1 +0.020 -0.027 -0.097

2 +0.150 +0.027 -0.127

Bilinear Leveling Grid:

0 1 2

0 +0.462 +0.180 -0.067

1 -0.002 -0.072 -0.150

2 +0.122 -0.010 -0.170

Bilinear Leveling Grid:

0 1 2

0 +0.422 +0.132 -0.105

1 -0.057 -0.140 -0.192

2 +0.075 -0.043 -0.215

Bilinear Leveling Grid:

0 1 2

0 +0.367 +0.082 -0.165

1 -0.110 -0.155 -0.233

2 +0.030 -0.102 -0.255

Bilinear Leveling Grid:

0 1 2

0 +0.347 +0.045 -0.190

1 -0.135 -0.180 -0.250

2 +0.002 -0.127 -0.280

Bilinear Leveling Grid:

0 1 2

0 +0.322 +0.032 -0.215

1 -0.155 -0.230 -0.280

2 -0.020 -0.142 -0.315

As you can see the variations in the measurements are very high.

This must be a known issue because Marlin does have a PROBING_HEATERS_OFF option but this would take even more time and I'm just curious if there is a reason for this or another fix to it.

I don't believe it would be a current issue since the power supply used can deliver many amps so it's probably something like electrical noise. I think it's fine to leave it because you only home and probe once during a print so the measurements would be 'accurate' but it would be reassuring to find out a reason and a possible fix.

I measured the rail with my oscilloscope and it actually isn't very noisy, whether I was heating or not. However, Vmax was 4.6 and Vmin was 4.4 and I'm wondering if that is too low. These voltages didn't change while heating so I think they are always that low.

Edit

For completeness, here an image of the printer:

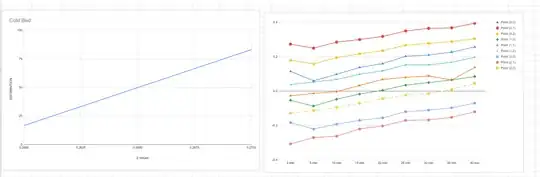

and here graphs about the BLtouch data over time: