There are several possible causes for this. From least to worst:

- The part itself is good, but the faceing cover plate is misaligned. No action needed.

- The part is mounted in a way that makes it wobble, re-mounting helps.

- The part is bad and needs to be replaced.

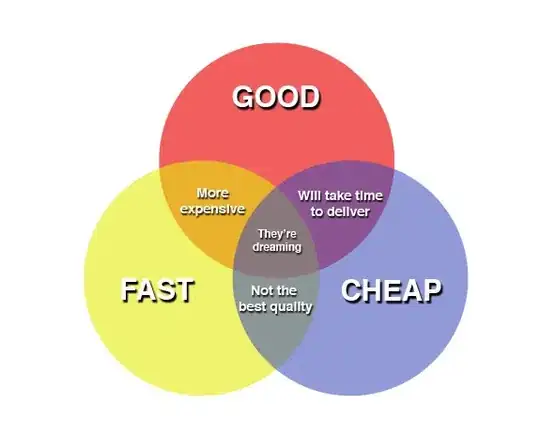

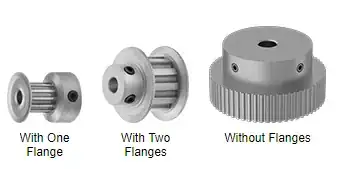

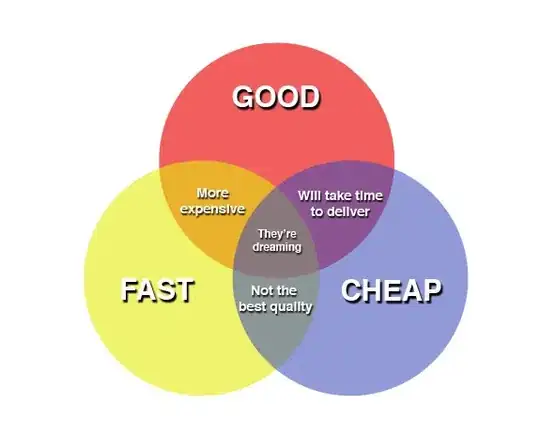

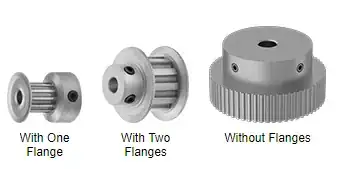

So, let's see the anatomy of a Timing Belt pulley. They exist in basically 3 general types in the McMaster Carr catalog: One flange, two flanges, no flanges. I am not affiliated with them, but they are pretty much one of the parts vendors in the industry that has almost everything, making them the convenience option. In the mantra, they are the "fast-good" option with the "everything" bonus and that the catalog of parts with 3D is integrated into fusion360. A similar supplier would be RS.

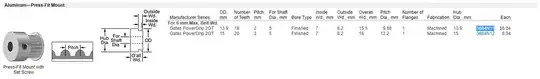

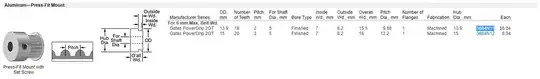

The part OP ordered is the "With One Flange" design, it is 6mm wide, 5mm axle and 16 teeth. The McMaster Carr catalog has two very close matches to OP's part: 3684N11 & 3684N12, about 6$ for a part machined from a solid piece. Why is that relevant?! well, the part OP ordered is not made from a solid piece but at least two parts: the body and one flange plate, as you can see on the product picture - the plate separation I marked with yellow here:

This is where the first error appears: if the flange isn't mounted centered (in poor quality it is rarely) then it appears to wobble but actually doesn't. But the video shows that the axis seems to be straight, while both the front and backside of the pulley wobble in the XY position. This means it is not just the flange that is mis-mounted on the part.

Now, error number 2 is misaligned mounting. In case the bore is good, you can often fix a misalignment by removing the part and mounting it again, more carefully, possibly using some thin shim metal around the axis. In some cases there is a pair of screws already to do this, if not it can help to modify the part with one or two extra alignment screws, allowing to sift the gear's center a slight bit by tensioning the additional screws.

In the case of OP's linked part, the screw that is not radial but protrudes next to the axis is designed to come over the flat of the axis and the other one is to tighten it down.

If the bore for the axis however is really skewed, and even after repeated re-mounting or shimming nothing can be done, a new part is needed. With the measurements of the part, you can order at a lot of online catalogs, the price and quality differ greatly. However, the engineering mantra strikes: