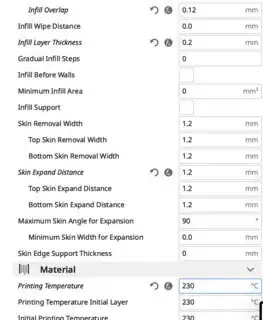

The cube is a 2 cm x 2 cm with infill at 30 % and layer height 0.2 mm, more details can be seen below.

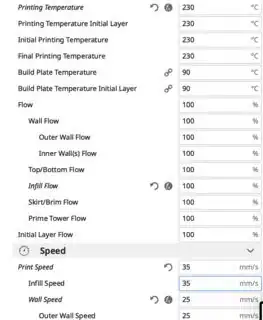

I'm printing with PETG using an Ender 3 printer.

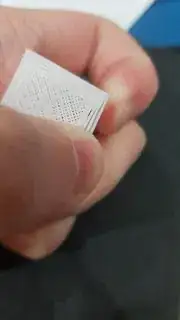

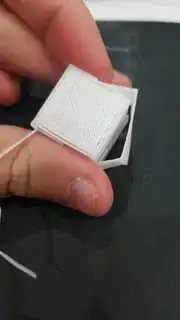

There seems to be a gap between the perimeter walls, I have already referred to other forums and specifically: " How to fix wall separation in 3D prints (gaps in between wall perimeters)? ", but I still can't find a solution for it.

Most would suggest to tighten up the pulleys, I've tried that, but that didn't work. Others also suggested tweaking to a higher temperature, again I've tried from a range of 230-250 °C, but this also failed.

Infill and initial/top layers seems to be strong and all lines are bonded except for the perimeter walls.

More details regarding the problem:

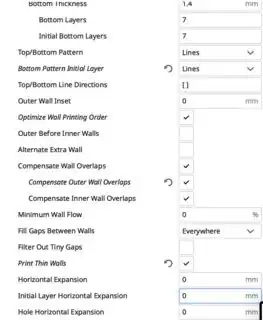

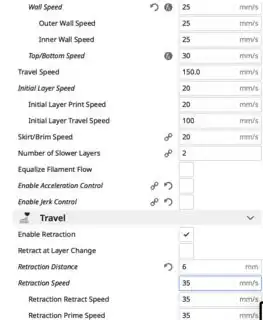

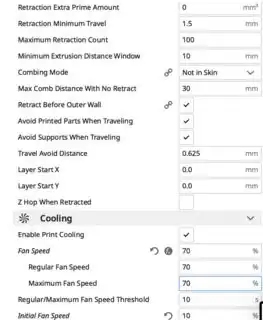

Here are my print settings: