I'm having an issue where prints with narrow tolerance come out fused. This makes it pretty much impossible to print anything with narrow parts. It seems to be mostly (maybe only) an issue in the bottom skin layers. Once it gets through those, the rest of the print goes smoothly and tight tolerances are not a problem.

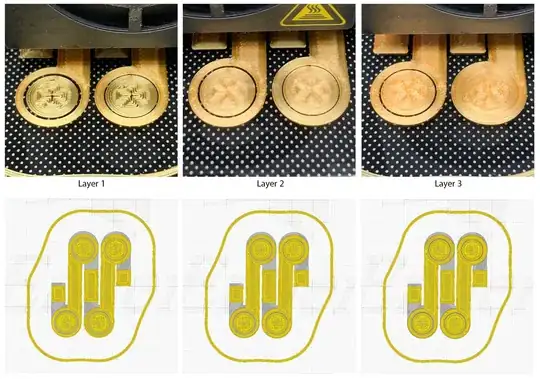

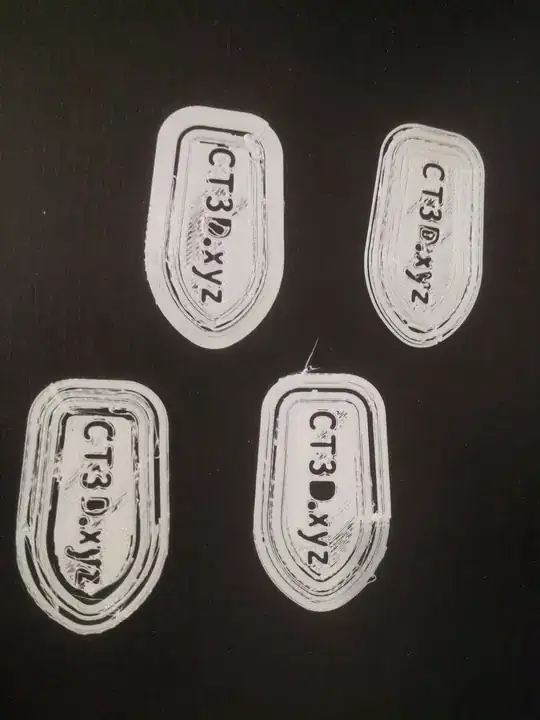

Here's an example where I've tried to print some hinges:

It's a test print where each hinge has a different tolerance, so the left and right are expected to look different. Below each real image is a preview layer from Cura showing how it's supposed to look.

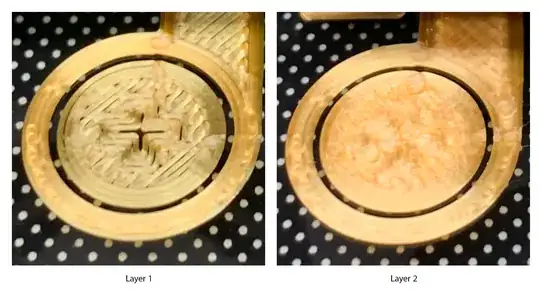

The first layer appears OK. The second layer looks a little messy, and the gap between inner and outer circles has shrunk. By the third layer the hinge on the right is completely fused.

The printer is an Ender 3 Pro with a glass bed (flat glass, no special surface), BLTouch, and Marlin 1.1.9. The slicer is Cura 4.6.1, and for this test print I used the default for "Super Quality - 0.12 mm" at 200 °C and 60 °C bed with no changes. The filament is Mika3D PLA.

Some things I've tried to fix this:

- Calibrated e-steps (currently set at 95.88) - no noticeable difference

- Calibrated flow rate (got 97.859 % but returned to 100 % for this test) - no noticeable difference

- Varying temperatures from 190 to 230 °C by 5 °C increments - no improvement from 200 °C

- Set "Initial Layer Horizontal Expansion" to -0.1 mm, -0.4 mm, and -1.0 mm in Cura. - no improvement.

- Set "Initial Layer Flow" to 90 %. - no improvement.

- Obsessively leveled and re-leveled the bed. - no improvement.

- Moved the Z-offset up and down to get more or less squish on the first layer - no improvement.

- Tried various brands and colors of PLA - problem is consistent.

- Reduced build plate temperature to 45 °C after initial layer - no improvement.

What else is there to check?

Edit 2020-06-26:

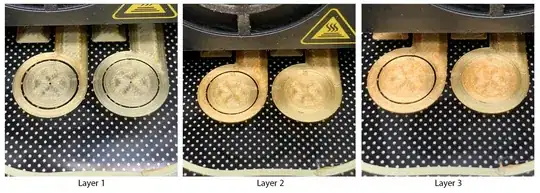

At R.. GitHub STOP HELPING ICE's suggestion I returned the e-steps to default (93), re-leveled the bed, and adjusted the z-offset tighter. I made 10 attempts with varying z-offsets, and here's the best one:

The first layer looks better! But the second and third layers are just as bad as before, in fact maybe worse. The circle on the right completely fused on only the second layer. And the top surface is just as ripple-ey and messed up as before.

Here's a closeup of the fourth layer to show how bad it is:

So although the re-calibrated e-steps may have been a problem, that clearly wasn't the only problem. What else should I be looking at here?

Edit 2020-06-27:

At Davo's suggestion I double-checked all my slicer settings. Flow is set to 100% everywhere, wall thickness is 0.8 mm for two walls (so 0.4 mm each), and nozzle diameter is correct at 0.4 mm.

At R.. GitHub STOP HELPING ICEs suggestion I double-checked my filament diameter. It is set to 1.75 mm. On the actual filament, my digital caliper measures 1.74 to 1.76, within the expected tolerance. So that doesn't appear to be the issue.

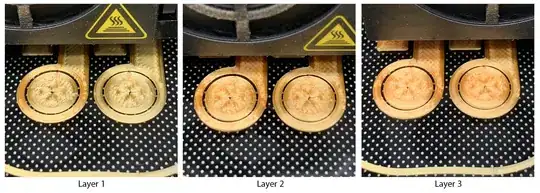

At 0scar♦s suggestion I tried a print with 0.2 mm layer height. Here's the first layer:

Looks like the same over-extrusion.

Looks like the same over-extrusion.

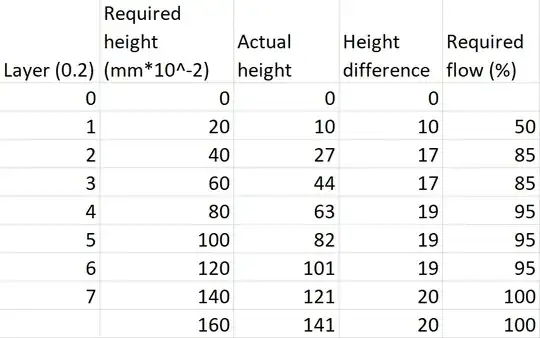

Then I tried reducing the flow multiplier to 90% (for both "flow" and "initial layer flow") and printing at 0.2 mm layer height:

Better, but it still looks over-extruded!

Better, but it still looks over-extruded!

I don't know what else to try.