Finally, I solved all faillures today.

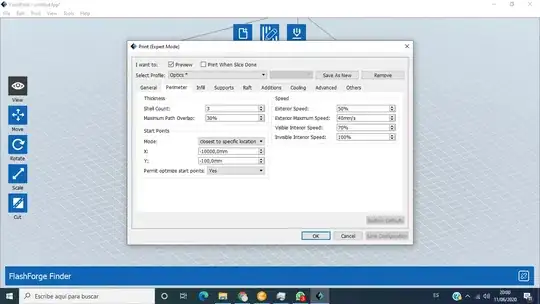

-When the bed is too close from the hotend:

I cheat the machine with a cutter patterns board over the bed at the first extruder calibration; the distance increases several times and then You can do it shorter.

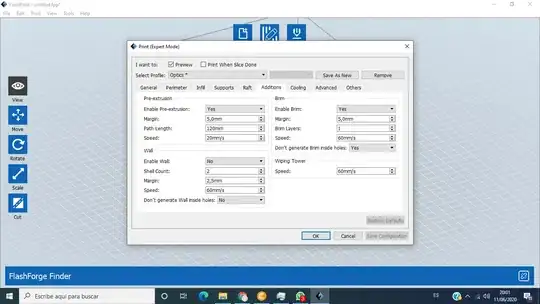

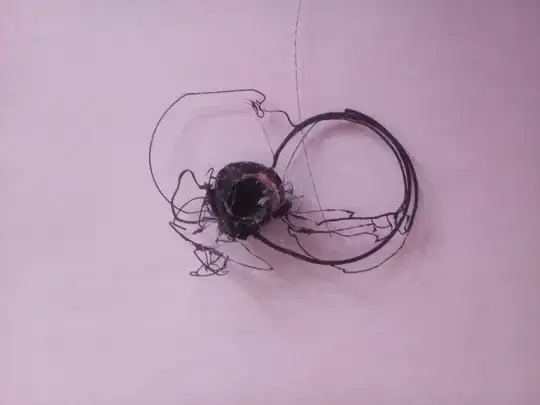

-The another half part of bad quality [low maintenance of the hotend]:

As a good newbie, I didn't know the periods of maintenance and the hotend had much plastic waste the PTFE tube welded and burned at internal, so the only option was to replace it for another same or to upgrade to "All Metal"; I chosen to upgrade with the replacement and I'll more maintenance to this zone.

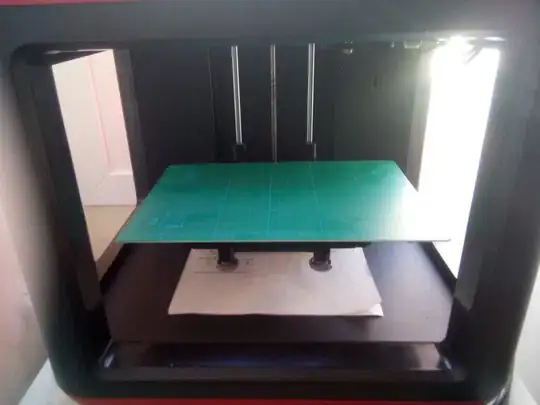

First attempt of trial piece:

...PANIC!

...PANIC!

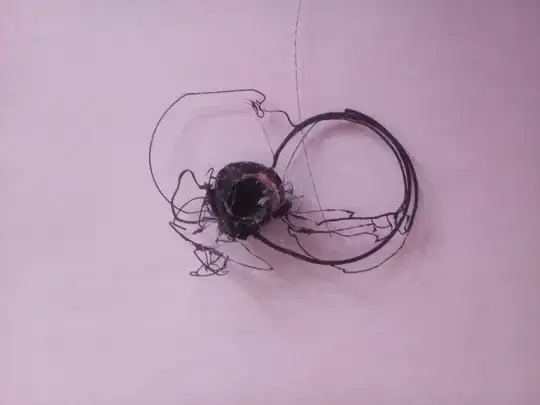

But then and FINALLY!

Almost all correct, I can continue with my printings.

Almost all correct, I can continue with my printings.

THANKS SO MUCH TO ALL, for your apportations and patience.