Depending on thermistor type you can get values from around 1ohm/C to 0.01ohm/C

so placing it on particulat place on heatbed (HB) could be very important. If objects are placed in the center then it's quite obwious that thermistor should be placed also in the middle.

Another issue in terms of thermistors are the wires. Because thermistors can be so sensitive then wires should have as less influence as possible on its temperature capacity. That's why wires and thermistor legs are so thin. Generally thiner than regular element's legs.

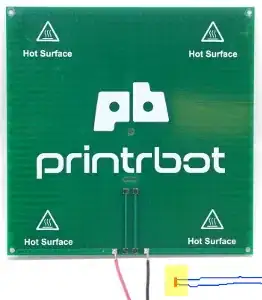

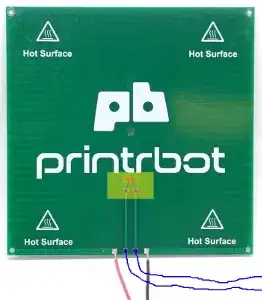

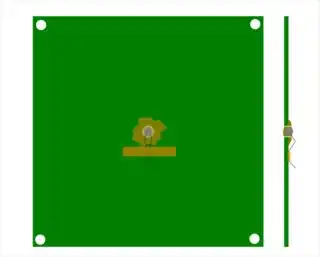

Answering your question - I would say it's better to put thermistor in the center hole, to use thermal grease in the hole so thermistor would have contact with HB. And personally I would use special thin wires to connect thermistor to the board. Kapton tape is then usefull to position thermistor head in the hole and in the thermal grease. Have a look on the picture.

I have such configuration. (In fact I got additional insulation as mentioned in this thread).

I would not recommend to use circuit board tracks as a thermistor connectors at all, but it's my opinion of course.

[edit]

Please be careful - thermal grease can be electrical conductor or insulator. You should choose insulator because short circuit thermistor legs will cause measuring impossible.

[edit2]

As you know HB is not even necessary when you print PLA so in this case it can be even better to not have heating at all than to overheat the bed. Because if you put your thermistor near to the edge of HB then (as said by Leo Ervin) the difference can be at level of 20C so if you heat around 70C and you get 90C your model can become soft on the bed surface and it will loose dimensions or you'll get elephant foot.

As stated in the comments - it's not really big deal whether you measure the temperature in the center of somewhere around. The issue is what level of perfection is ok for you.