Short answer

Usually no.

Long answer

There are several big factors that limit how small things you can print. The bigger ones are pretty much:

- Positional accuracy and settings (limited by steps/mm in X, Y, Z)

- Nozzle diameter

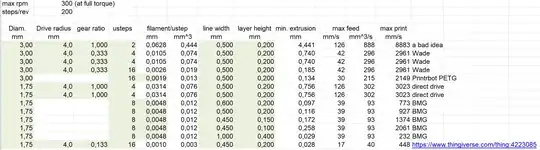

Now, why don't you need to care about steps/mm on the extruder that muchin the grand scale compared to the positional accuracy? Well, we have 1.8° per step, from which, with the diameter of the gear, 11mm, we get 0,1778 mm of filament extrusion or 0.428 mm³ of extruded plastic per full 1.8° step - which clearly is unsuitable to printing at all. But with the 16 micro-steps the shorter movements are possible and a single micro-step extrusion is in the area you calculated - I got to 0,0267 mm³, possibly the result of different rounding between us. With an assumed effective gear diameter of 11mm (usually the effective gear diameter is a little smaller, thus the 93 steps) we come to about 89.9 steps per mm of filament, which corresponds to about 2.4 mm³ of extruded plastic, or about 30 mm of line (with your given parameters), bringing us to about 3 microsteps per millimeter of line on the tray. So far, your math checks out. But that usually shouldn't be too much a limiting factor. We know from your given settings, that the Configuration.h will look like this, putting the microsteps into the steps/mm:

/**

* Default Axis Steps Per Unit (steps/mm)

* Override with M92

* X, Y, Z, E0 [, E1[, E2[, E3[, E4]]]]

*/

#define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 400, 93 }

As you don't have a micro-stepping driver, this part in Configuration_adv.h is non-functional:

// Microstep setting (Only functional when stepper driver microstep pins are connected to MCU.

#define MICROSTEP_MODES {16,16,16,16,16} // [1,2,4,8,16]

With the proposed 0.4 mm/0.2 mm line, we are still somewhat on the good side, allowing us about 1/3rd of a millimeter as the shortest line printable as a single step extrusion. That's a consistent with printing a simple, circular dot being printable with these settings - 0.4 > 1/3.

But once you get to smaller nozzle diameters, the limitation gets more noticeable: at a 0.2 mm nozzle and 0.22 mm line at 0.1 mm height, that's a 0.022 mm² crosssection, so the 1-step extrusion is equivalent to a full millimeter of line! That's much more bothersome in theory.

However, I haven't been able to witness the inability of showing that limit of lacking extrusion yet on my TronXY-X1 with a 0.2 mm nozzle - the steps/mm in it are also about 90-100 last I set them. The TronXY uses a very similar (virtually identical) extruder setup as the Ender 3, and it achieved printed lines of about 0.3 mm length at 0.1 mm layer height somewhat reliable, but the retraction made huge issues, which might also mask the problem.

I believe that it needs these smaller nozzles to amplify the problems to make them noticeable. It also should become more noticeable if you'd use 2.85 mm or 3 mm filament.

Ways to improve resolution

However, if printing with smaller nozzles, it might be a good idea to think about how one could improve the accuracy of the extruder system.

The most-easy way would be to alter the extruder and swap the gear to one of a smaller effective diameter - That way a single step accounts to less extrusion, which means, in turn, a higher number of steps/mm, and thus allowing for shorter extrusions that can be still achieved.

Next one might think about getting a different motor/driver setup that might have either more microsteps or generally a smaller step size.

Quadrupling the effective (micros)steps/mm would allow us to print about a 0.25 mm line on the 0.22 mm nozzle I proposed, being pretty much a spot - if it wouldn't be partially masked in other issues as I experience.