I have a Printrbot LC with the following extruder gears:

Stepper on the right, filament toothed gear inside, same size of the small stepper gear.

I don't have much more information besides the model of the motor (42BYGH4807), but the reduction ratio (NEMA stepper -> toothed gear on the filament) is about 2:1, the filament is pushed at half the circumference speed of the stepper motor gear (small on the photo).

I am using 3 mm filament with a 0.4 mm nozzle and I can print at 80 mm/s without particular issues.

I would like to switch to 1.75 mm filament and sometimes use 0.8 mm nozzle, meaning that I need the filament to be pushed faster:

- 3 mm vs 1.75 mm means 3x faster

- 0.8 mm vs 0.4 mm nozzle it's another 4x speed

- using Klipper firmware I may likely set a higher linear print speed, so there could be another 1.2x speed factor for the filament.

However, I'm not sure how far I am right now from my current maximum extrusion speed. Maybe I'm already at near the max, maybe I still have a 2-3x safety margin.

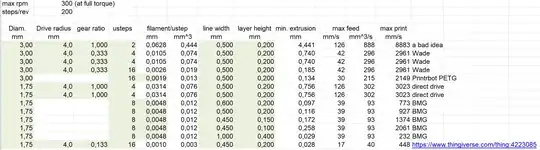

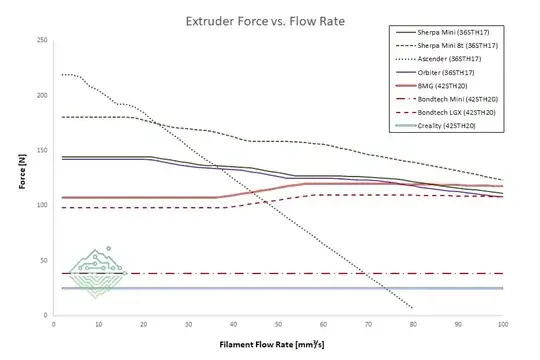

Since I will likely need to change the extruder gears to push the filament 15x faster I wonder how to calculate the optimal gear ratio given an expected maximum linear printing speed, filament diameter and nozzle diameter.

Since stepper motors get less and less torque at increasing stepping rate, maybe the answer depends also on filament viscosity and microstepping settings?