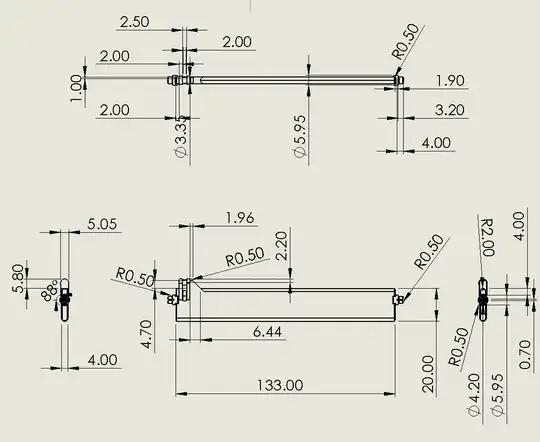

Dimension-wise it's probably ok.

If you want to print it as a single piece it would be quite challenging because of the cylinders, overhangs and bridges present in multiple directions: overhangs and bridges result in lower quality and precision, while cylinders can be printed nicely only when their axis is vertical.

However I see that you could easily split the component into multiple parts, each one of which could be printed optimally.

You can glue the different parts together and you are done, see What glues for PLA? and What glues to use for PETG?